Table of Contents

Why is something as personal as jewelry still limited to one-size-fits-most? We’re living in an age of personalization, rapid prototyping, and 3D printing, yet when it comes to buying a ring, bracelet, or necklace, most customers are still forced to choose from rigid size charts and hope for the best from custom jewelry sellers.

Take Rachel, for example. She had been looking forward to the ring for weeks. It was everything she wanted, delicate silver, a swirling design, and a soft aquamarine stone. But when it arrived, she hesitated. The brand’s website had asked her to pick from preset sizes: 6, 7, 8, 9. She chose size 6, the closest to what she usually wore. But once on her finger, it didn’t quite feel right. It wasn’t tight enough to be secure or loose enough to be comfortable. She wondered, Why can’t I just give them my actual size?

It’s a question many jewelry buyers have asked. The truth is, most of us don’t fit neatly into presets, and that’s where parametric design and digital fabrication begin to reshape the experience.

What is Parametric Jewelry Design?

Parametric design is a method where a 3D model is driven by user-defined inputs, or parameters. Instead of redrawing or remodeling jewelry for each customer, designers create a dynamic model that can automatically adjust based on sizing or style preferences.

For example, a ring design can include adjustable parameters such as finger diameter, band width, stone size, and metal thickness. When the customer inputs their exact size, say, 16.4 mm instead of choosing between US size 6 or 7, the design updates instantly while maintaining its proportions and beauty intact. That’s the advantage parametric design brings to custom jewelry.

Custom Jewelry: From One Design, Many Bodies

Here’s how parametric design empowers custom jewelry creators and wearers alike:

1. Consistent Aesthetic Across All Sizes

One of the biggest challenges in traditional resizing is maintaining the original proportions of a design. Manually adjusting the size of a ring, especially a detailed one, often means cutting and reshaping the band, which can compromise both structure and style. As noted by the Australian Diamond Company, even small changes carry risks, and intricate designs are particularly difficult to resize without distortion. Parametric design eliminates this issue by scaling every element proportionally.

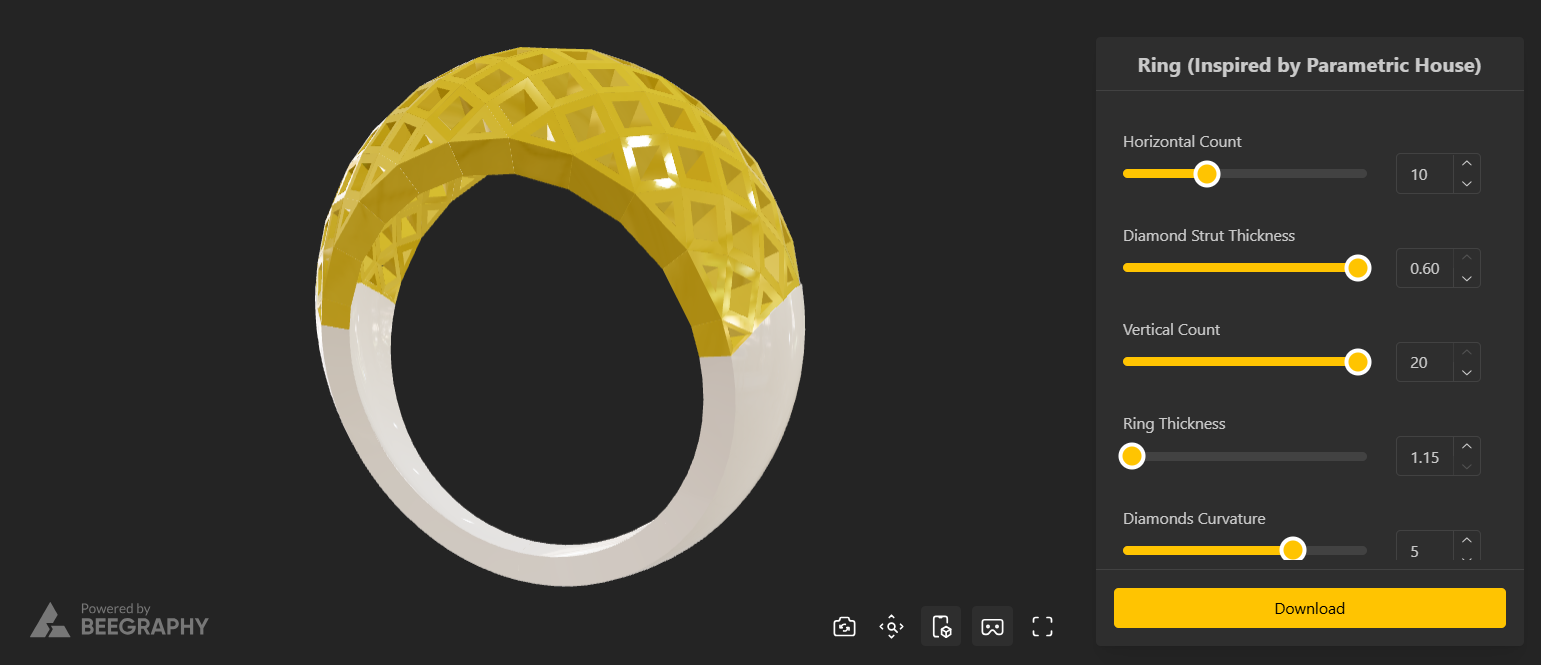

An excellent example of this is a parametric ring design by Robert Rodriguez inspired by the design of a parametric house. The piece reimagines the building’s flowing contours into a wearable form, capturing its spatial rhythm through precise geometry. What makes this design even more remarkable is its adaptability: the ring maintains its sculptural integrity and visual harmony regardless of the wearer’s finger size. This approach to scale and proportion earned the piece the winning title in the Fashion & Jewelry category of the BeeGraphy Computational Design Awards, showcasing how parametric thinking bridges architectural language with personal adornment in a truly seamless way.

2. Custom Fit at Scale

Using product configurators, designers can create a base model for a ring, then define adjustable parameters like:

- Ring size (diameter)

- Band width

- Gemstone size

- Metal thickness

With this system, customers can input their exact measurements on a brand’s website via a configurator interface, and instantly preview how the jewelry will look. The design is then exported for 3D printing or production without human rework.

Parametric Ring Design

Take a look at the model above by Robert Rodriguez to understand it better. You can interact live with this award-winning model here. Change the ring size, band width and the curvature to your comfort, and your custom ring is ready. To build such configurable models, check out Configurator.tech, a product configurator powered by BeeGraphy.

3. Adaptive Design for All Genders and Body Types

Jewelry has long been designed around binary genders and idealized proportions, standard ring sizes, average wrist measurements, and earrings that overlook stretched lobes. But bodies don’t follow templates. Parametric design allows a single design language to flex across diverse body types, adapting intelligently to individual needs.

Brands like Omerica Organic serve stretched ear jewelry markets with multiple gauge sizes, though they still rely on fixed presets. Parametric models could let customers adjust plug diameter, flare width, and dangle length in real time. Similarly, Automic Gold promotes size- and gender-inclusive design, and could further elevate that mission by scaling each piece precisely to the wearer’s dimensions; no resizing or compromises required.

This level of adaptability doesn’t just improve the fit; it redefines inclusivity by creating jewelry that fits the person, not just the body.

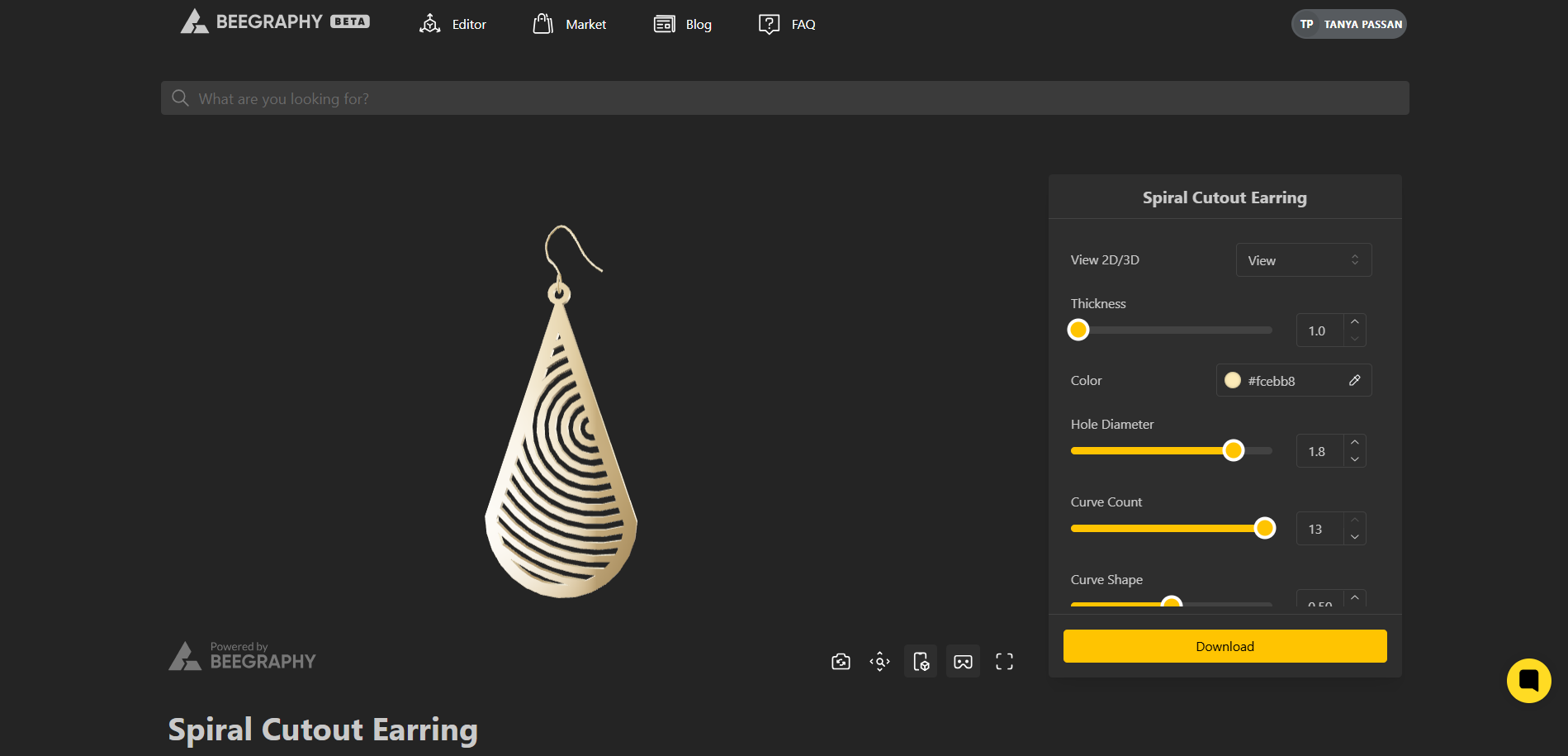

4. Real-Time Iteration with Clients

Parametric design makes client consultations more interactive than ever. Designers can adjust parameters live, whether it’s narrowing the band, raising the stone setting, or modifying the overall proportions, simply by moving a slider. This creates a collaborative design process where clients can see their preferences reflected instantly, ensuring clarity and satisfaction before the piece goes into production.

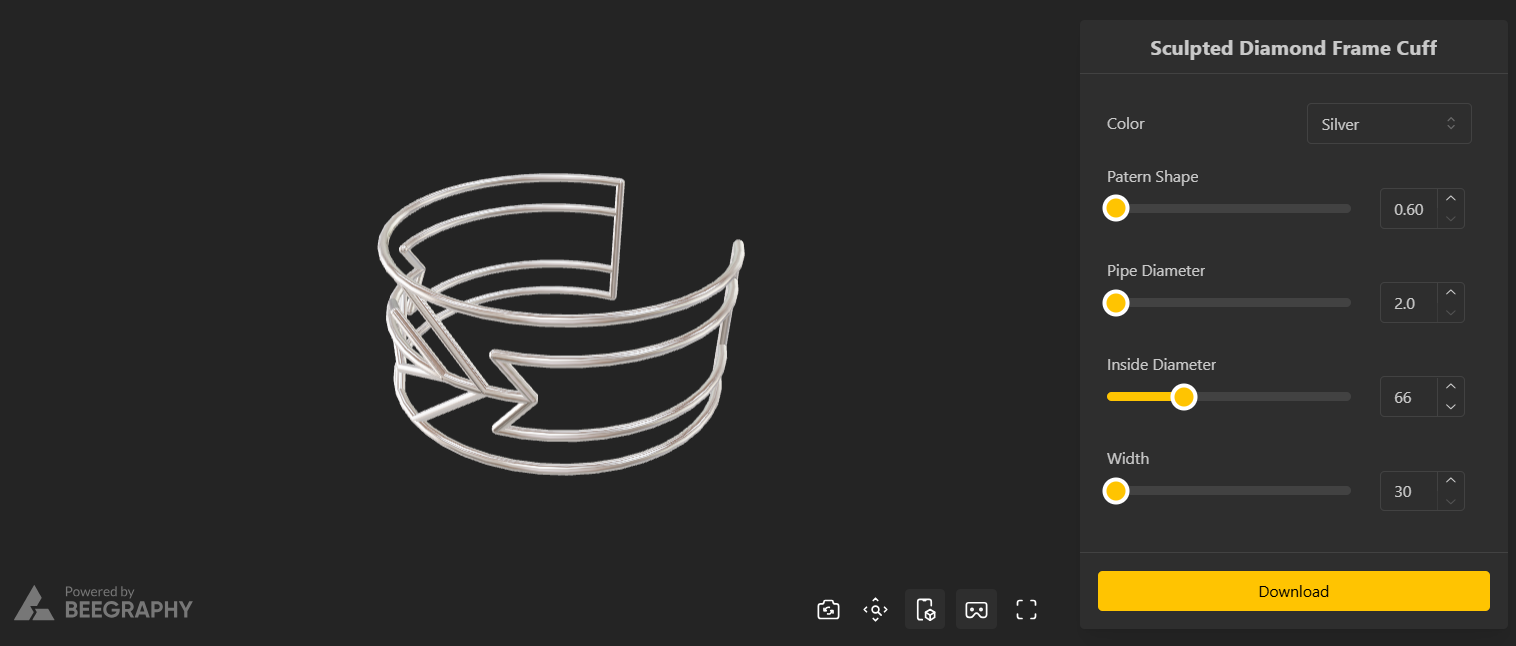

Curious how it works? Try customizing this Diamond Frame Cuff and see the changes come to life in real time.

Diamond Frame Cuff

5. Scalable Personalization

Parametric systems empower brands to deliver true personalization at any scale, whether serving ten customers or ten thousand. Once a model is built with adjustable parameters, each order adapts automatically to customer input, without manual intervention or repeated modeling.

For example, GLAMIRA, a global custom-jewelry brand operating in over 65 countries, generates nearly 50% of its citrine ring revenue from digitally customized orders, proof that scalable personalization is possible when powered by software, not manual labor.

Custom Ring Designs by GLAMIRA

Sustainable Customization at Scale

Parametric design not only improves fit but also streamlines operations and reduces environmental impact. By producing only what’s ordered, at the exact dimensions needed, brands can eliminate excess inventory, minimize returns from poor sizing, and avoid manual resizing altogether. Whether using 3D printing, CNC, or casting, this workflow saves both materials and labor, making customization more sustainable and cost-effective.

To explore the best 3D Printers available to print your unique jewelry designs, explore the video below.

Jewelry That Adapts to You, Not the Other Way Around

For Rachel, and countless others, parametric design offers a better way to experience jewelry designed to fit them, not the other way around. It’s more than personalization; it’s a quiet revolution in how we think about product design: responsive to human variation, respectful of individuality, and built for modern digital workflows.

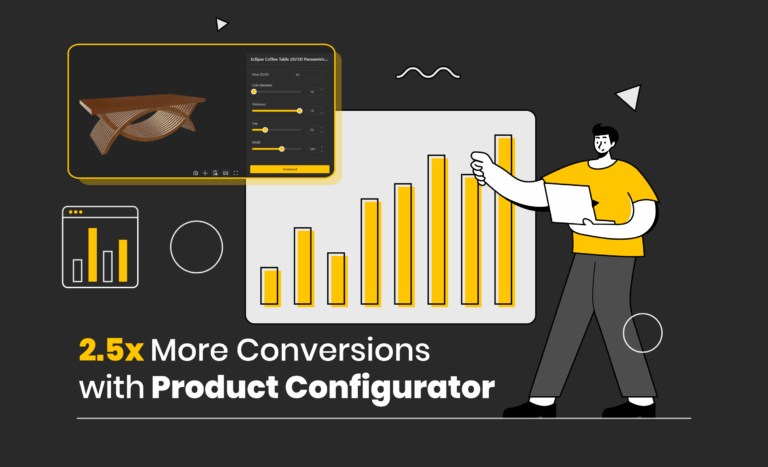

Custom Jewelry Configurator by BeeGraphy

Scaling Personalization Without the Overhead

Whether you’re a designer or a brand, now’s the time to create custom jewelry that meets people where they are. With the BeeGraphy Editor, you can build parametric models that adapt to individual needs, while Configurator.Tech enables live, interactive sizing directly on your website, offering customers a truly personalized experience.

And it doesn’t stop at customization. Configurator.Tech, powered by BeeGraphy, makes the entire process scalable. One parametric model adapts instantly to each customer’s input. No manual edits, no repeated modeling. It streamlines production from click to creation, making personalized jewelry not just possible, but practical for growing businesses. Whether you’re selling one piece or a thousand, every order is made-to-measure and ready for production.