Table of Contents

Introduction

As design methods become more data-driven, BeeGraphy is leading the way with dynamic fabrication methods that connect computational design to real-world production. Its visual interface makes computational design easier to perceive, linking the exploration of ideas directly to fabrication via Beegraphy’s own configurator.

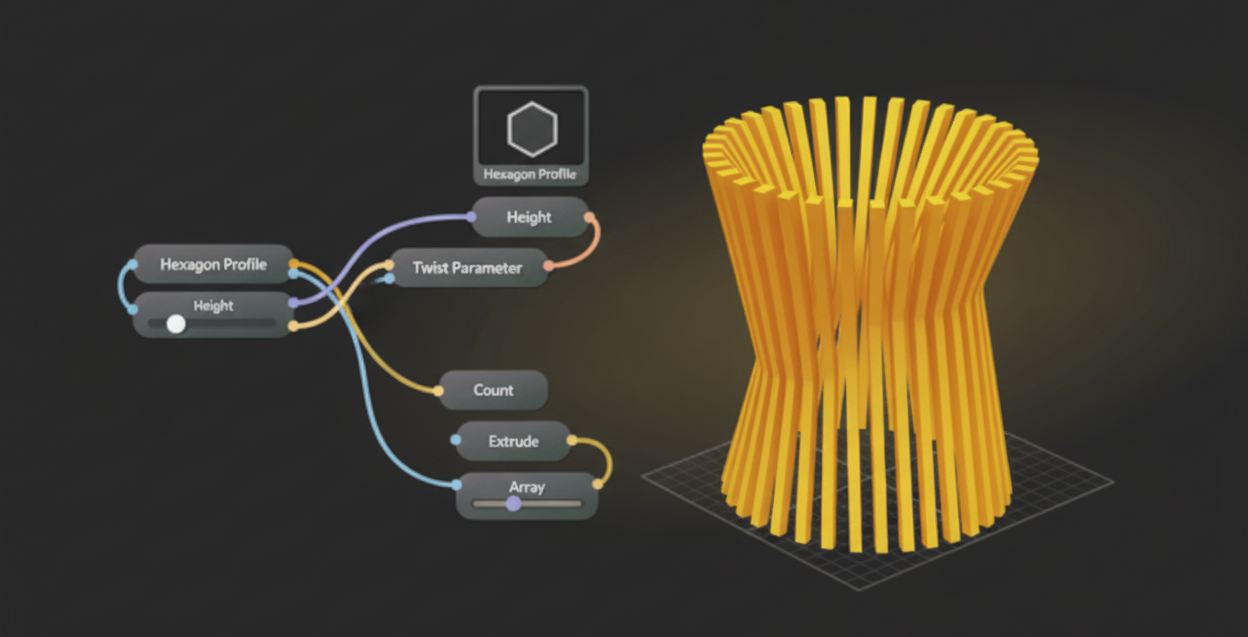

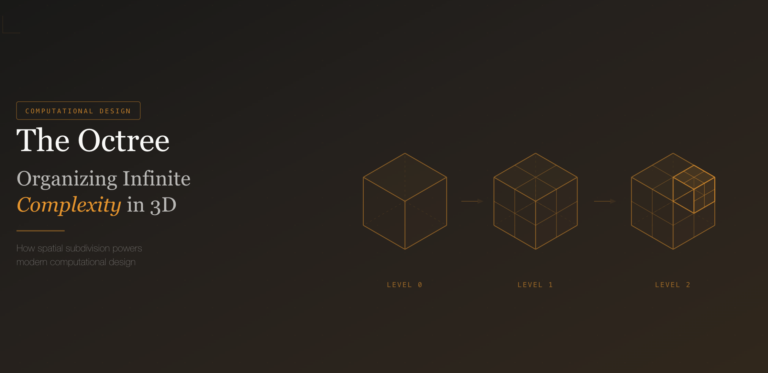

Computational design uses algorithms, programming, and parametric modelling to create, iterate, test, and improve design solutions. In the past, this method needed advanced coding skills, repeated workflows and tedious iterations. However, improvements in visual programming now let designers build complex algorithms using drag-and-drop tools. BeeGraphy shows this progress by enabling users to create workflows based on nodes, where each geometric part is controlled by parameters that can be changed instantly, leading to nearly limitless design options.

Parametric design is not just about looks. By embedding rules and limits within the workflow, designers can improve material use, structural strength, daylight access, sound quality, energy efficiency, and spatial layout. These features support quick iterations, mass customization, and a smooth link between digital design and real-world production. BeeGraphy models can directly contribute to fabrication planning, CNC toolpath generation, and online configurators, allowing designs to move effortlessly from screen to physical form.

The next sections will examine how parametric designs created in BeeGraphy can be brought to life through manufacturing methods such as CNC milling, laser cutting, 3D printing, and robotic fabrication, connecting the virtual and physical worlds through parametric logic.

Understanding the power of Beegraphy

The strength of BeeGraphy is its visual programming environment. This feature makes complex algorithmic logic easy for those without traditional coding skills. Designers can adjust relationships, dependencies, and constraints using simple drag-and-drop nodes. This helps them create, modify, and improve complex forms quickly and easily. The visual approach allows designers to concentrate on creativity and problem-solving instead of repeating workflows to produce different versions while collaborating with others in real time.

BeeGraphy also supports parametric systems that adapt to external data or changing needs. Designers can directly integrate environmental factors, structural considerations, or user inputs into their workflows. This results in designs that are responsive, optimized, and context-aware. For example, a parametric façade could change its pattern to maximize daylight while minimizing heat gain.

Another significant advantage is fabrication possibilities. BeeGraphy outputs can be connected to multiple fabrication processes, web-based Beegraphy’s very own configurator, or mesh slicers. This allows designs to move smoothly from the concept stage to real-world production. It supports quick prototyping, customizability, and efficient use of materials.

In short, BeeGraphy helps designers think in systems instead of static forms. It transforms parametric design from a specialized technical area into a flexible, accessible, and production-ready method. It links digital design logic with physical fabrication.

Fabrication Methods in Beegraphy

Fabrication is the process of transforming a digital design into a real, physical product. It plays an important role in linking ideas to practical uses. This allows designers, architects, and engineers to think, test, refine, and implement their creations. While designing in BeeGraphy emphasizes the parametric and algorithmic aspects, where geometry is managed, improved, and changed through nodes and parameters, fabrication aims to turn those digital designs into functional, usable forms.

In computational design, fabrication isn’t just about making an object. It also involves understanding material properties, the limits of manufacturing processes, and how design intent interacts with physical reality. Parametric models created in BeeGraphy are flexible, meaning the same design can fit various fabrication methods, be scaled to different sizes, or adjusted to meet performance needs without needing to redo the model from scratch.

Here, a model has been created in BeeGraphy. Let’s explore the fabrication processes we can choose from. This exploration includes techniques like CNC milling, laser cutting, 3D printing, and robotic fabrication. Each method has unique possibilities, from quick prototyping to precise production of complex shapes, and allows designers to use their parametric workflows to the fullest. By understanding the available fabrication techniques, designers can make smart choices about how to turn digital creativity into physical objects, optimize material use, and test designs in real-world scenarios.

Fabrication is where digital creativity meets physical limits. Understanding it is essential for anyone wanting to connect the virtual and real worlds through computational design.

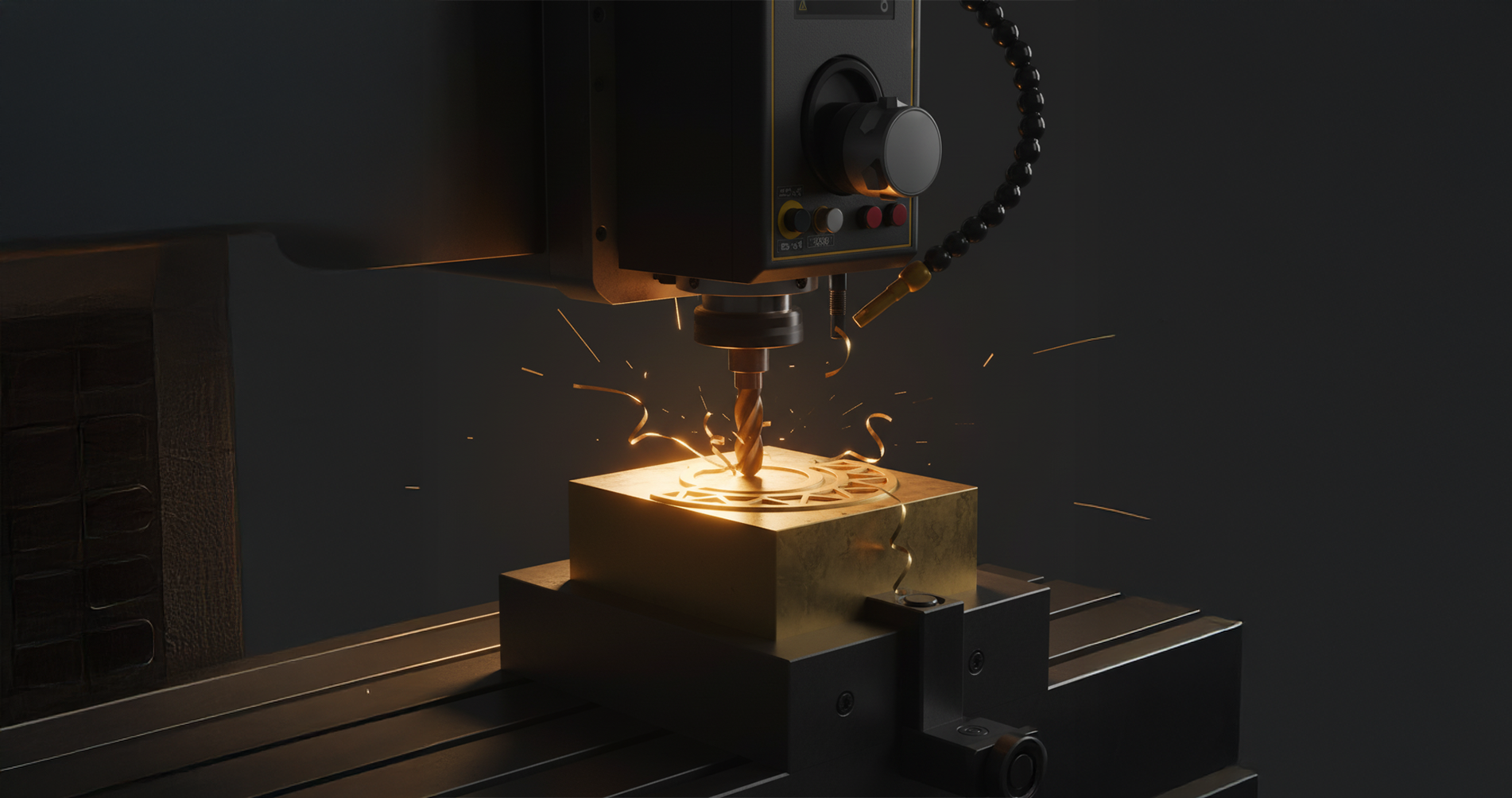

1. CNC Fabrication (Subtractive Manufacturing)

Best for: Wood, MDF, acrylic, aluminum, foam

CNC (Computer Numerical Control) machining is a subtractive manufacturing process in which pre-programmed computer software controls machine tools to remove material from a solid block (metal, wood, plastic, or other materials) to create precise shapes and components. Unlike manual machining, CNC machines follow exact digital instructions, allowing for high precision, repeatability, and complex geometries that would be difficult or impossible to achieve by hand.

Applications:

- Parametric furniture

- Modular facades

- Topographic surface panels

Workflow:

Beegraphy → Export geometry → CAM software → CNC machine

2. Laser Cutting

Photo by Cemrecan Yurtman: https://www.pexels.com/photo/modern-laser-cutter-in-industrial-environment-29988967/

Best for: Thin materials like acrylic, plywood, metal, or cardboard

Laser cutting is a fabrication process that uses a focused laser beam to cut, engrave, or etch materials with high precision. The laser melts, burns, or vaporizes the material along a defined path, creating clean and accurate cuts. This method works with a wide range of materials, including wood, acrylic, metal, cardboard, and fabric, and is particularly suited for 2D profiles, patterns, and interlocking components.

Applications:

- Parametric lighting fixtures

- Slot-based assemblies

- Patterned partitions

Workflow:

Beegraphy → 2D layout export (.DXF/.SVG) → Laser cutter

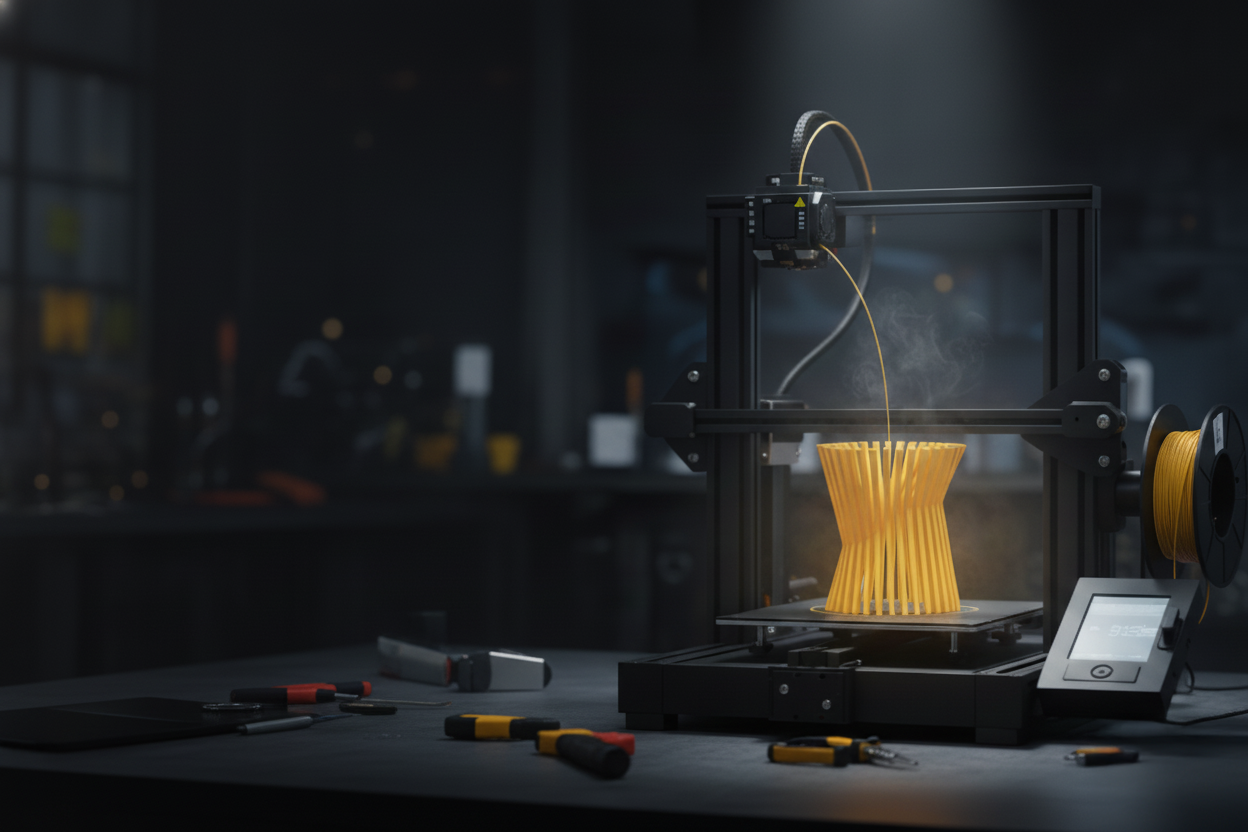

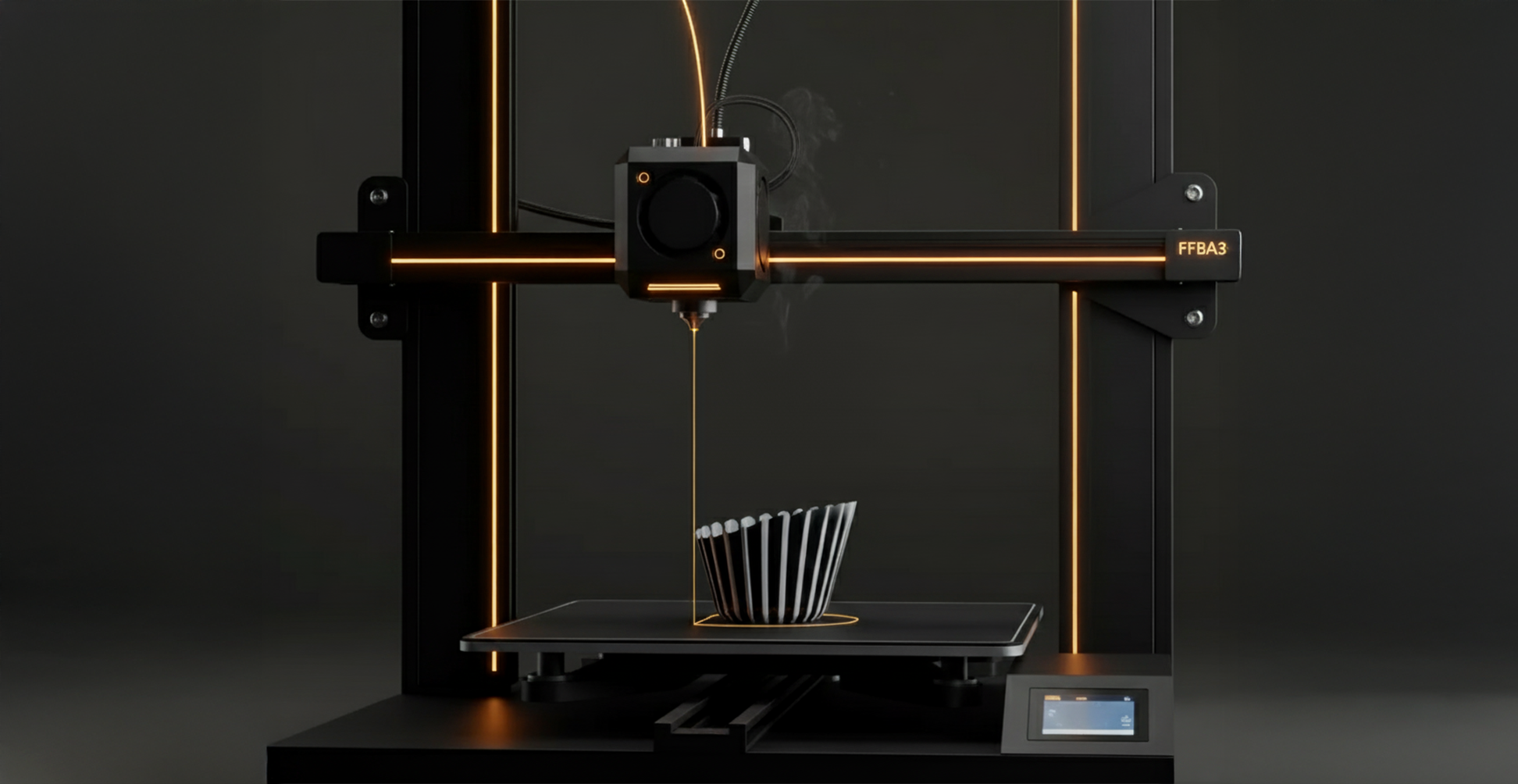

3. 3D Printing (Additive Manufacturing)

Best for: Plastic, resin, or metal printing

3D printing, also known as additive manufacturing, is a fabrication process in which an object is built layer by layer from digital models. Unlike subtractive methods such as CNC machining, 3D printing adds material only where it is needed, allowing for complex geometries, internal structures, and customized designs that are difficult or impossible to produce with traditional methods.

Applications:

- Sculptural art pieces

- Product prototypes

- Custom mechanical parts

Workflow:

Beegraphy → .STL export → Slicer software → 3D printer

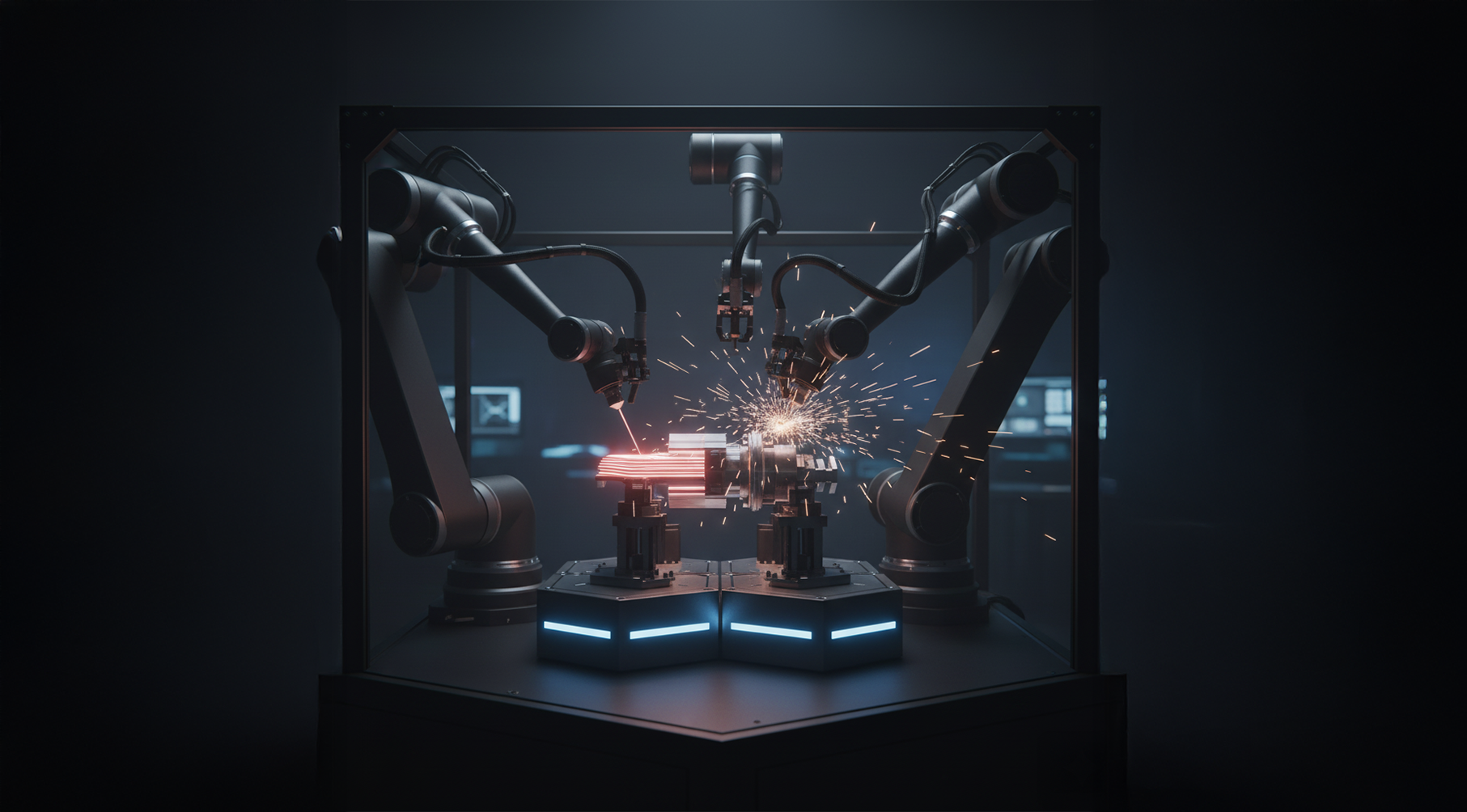

4. Robotic Fabrication

Best for: Large-scale or adaptive fabrication projects

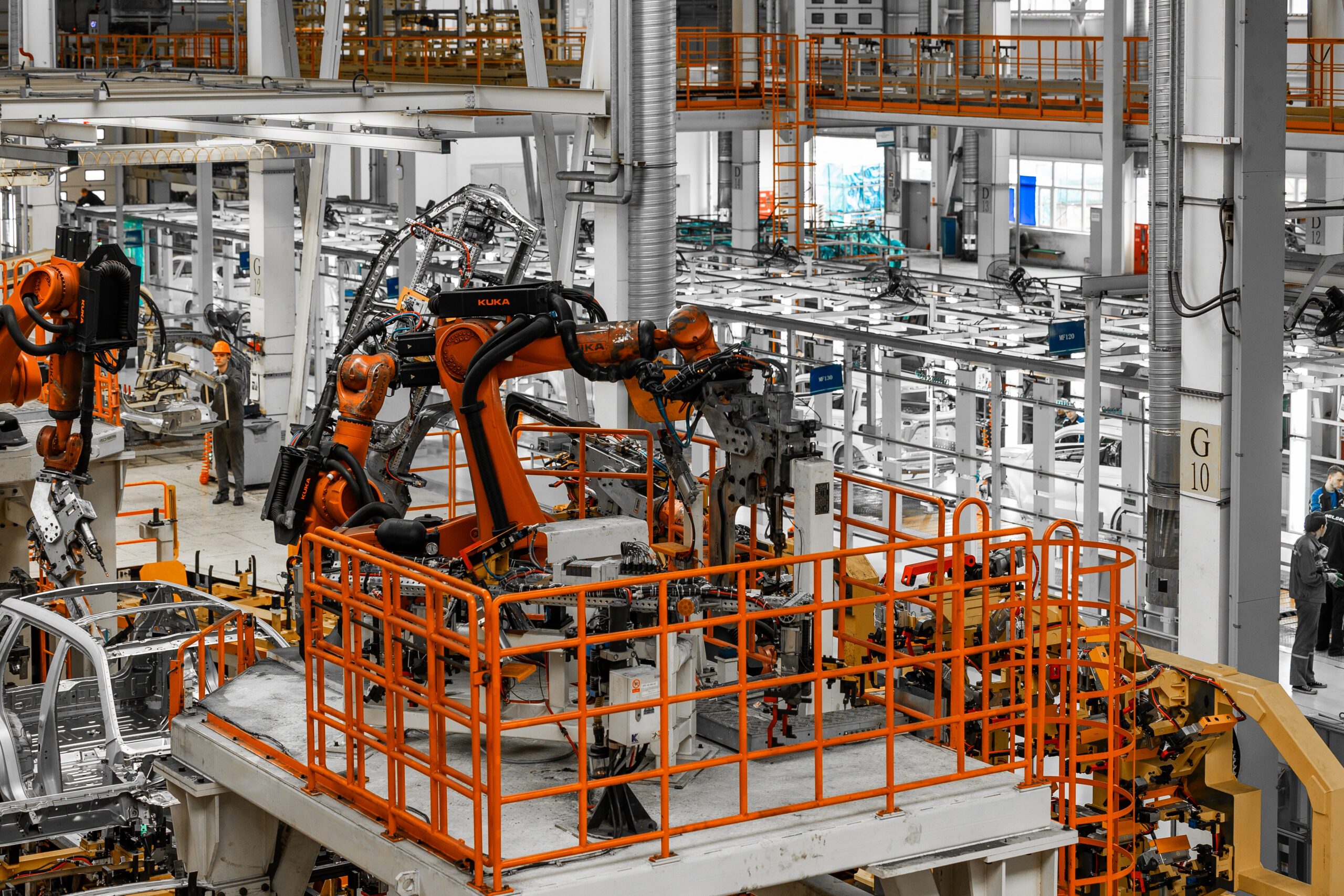

Robotic fabrication is a computer-controlled manufacturing process in which industrial robots are programmed to perform tasks such as cutting, assembling, 3D printing, or material deposition with high precision and repeatability. Unlike traditional manual or stationary machines, robots can move freely in multiple axes, enabling complex, large-scale, or non-standard geometries to be fabricated efficiently.

Applications:

- Custom façade panels

- Clay or concrete 3D printing

- Adaptive molds or bending systems

Workflow:

Beegraphy → G-code → Robotic control software (KUKA, ABB, RoboDK, etc.)

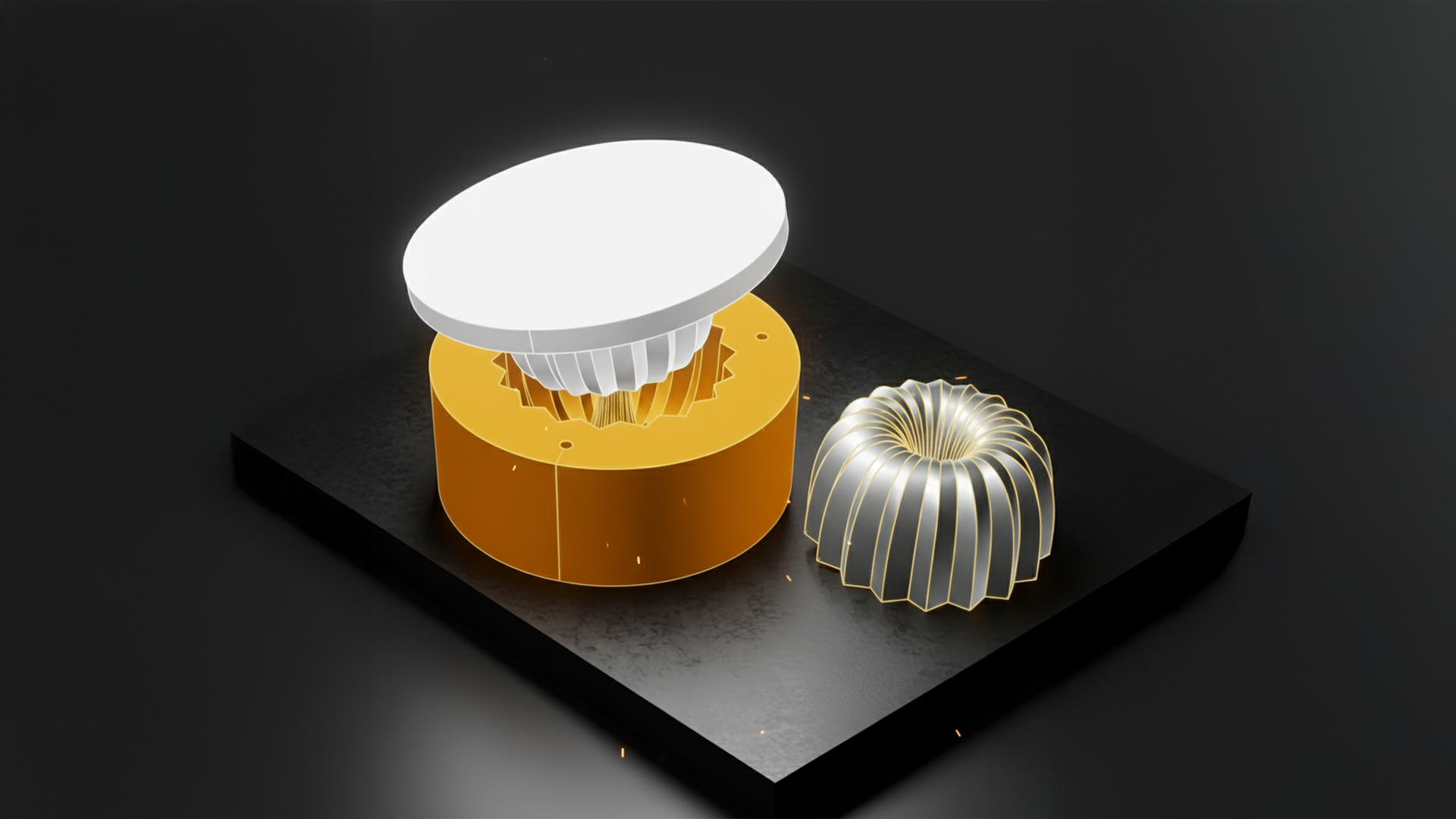

5. Digital Molding & Casting

Best for: Resin, silicon, concrete, or plaster prototypes

Digital molding and casting is a fabrication process where parametric or digital models are used to create molds, which are then used to reproduce objects in materials such as resin, concrete, plaster, or metal. Unlike traditional mold-making, the design is first created or optimized digitally—often in platforms like BeeGraphy—allowing precise control over geometry, tolerances, and complex features.

Applications:

- Concrete tiles

- Resin-cast jewelry

- Product casings

Workflow:

Beegraphy → Mold geometry export → Fabricate mold → Cast material

6. Hybrid and Modular Fabrication

Best for: Multi-material or modular assemblies

Hybrid and modular fabrication is a production approach that combines multiple fabrication techniques or breaks a design into interconnected modules to optimize efficiency, material use, and scalability. Hybrid fabrication may integrate methods such as CNC milling, 3D printing, laser cutting, or robotic processes within a single project, leveraging the strengths of each technique to achieve complex or multi-material outcomes.

Applications:

- Installations and art pieces

- Educational kits

- Modular furniture

7. Configurators and Automated Fabrication Pipelines

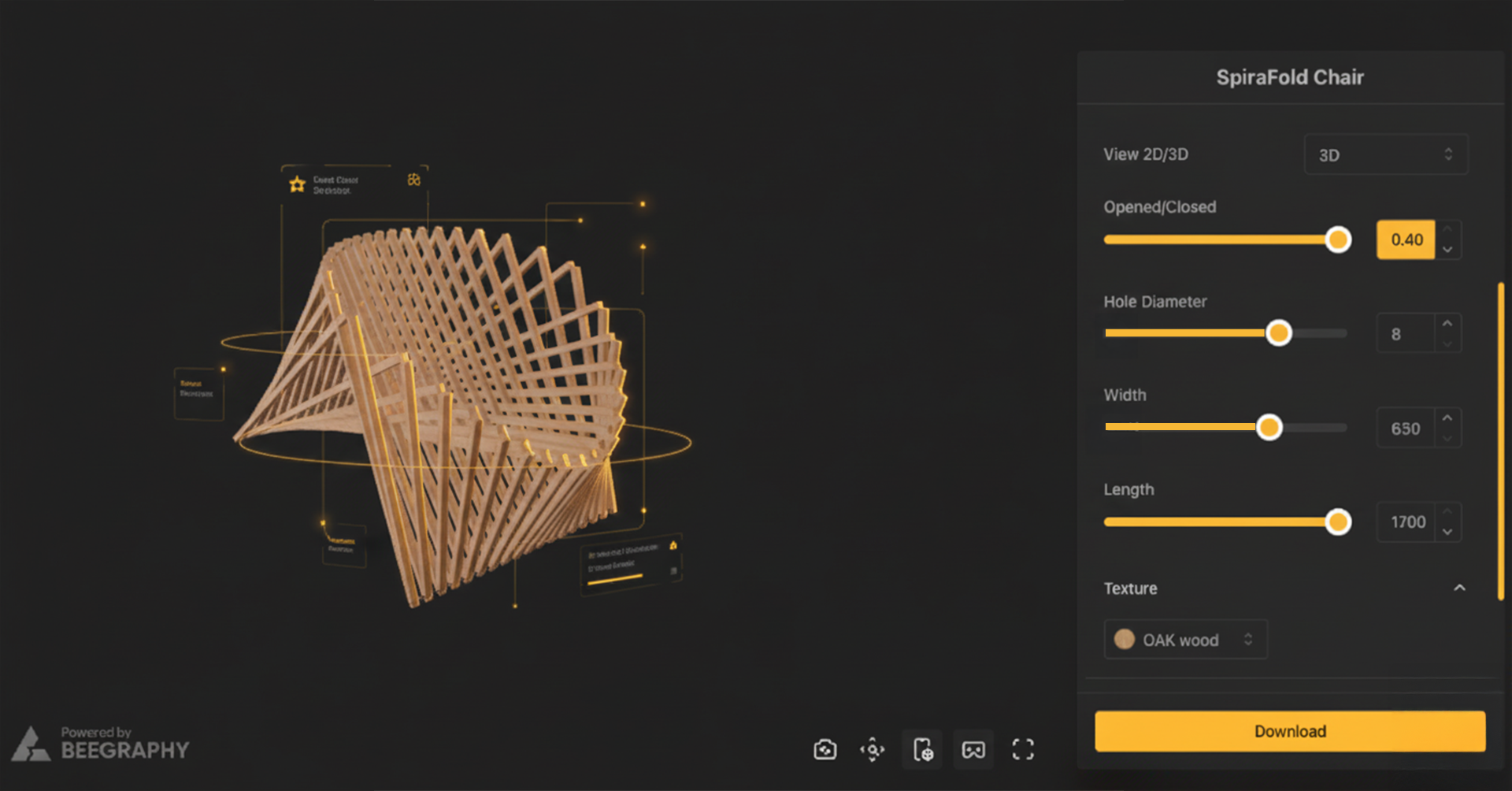

One of Beegraphy’s most powerful potentials is web configurators, interfaces that allow users or clients to customize parameters in real-time. Once they finalize a design, Beegraphy can automatically generate fabrication-ready files (CNC, 3D print, laser cut, etc.).

Applications:

- Custom furniture platforms

- Personalized product systems

- Interactive architectural components

Workflow:

Beegraphy → Configurator → Automatic DXF/STL generation → Manufacturing

Conclusion

BeeGraphy shows the transformative power of parametric and computational design by making algorithmic workflows easy to access and use. Its real strength is in connecting virtual design with physical fabrication. By controlling geometry in a parametric way, designers can create endless design variations while setting rules and limits that improve performance, material use, and appearance.

Exploring fabrication methods like CNC milling, laser cutting, 3D printing, robotic fabrication, digital molding and casting, and hybrid or modular techniques demonstrates the many ways to bring BeeGraphy creations to life. Each method has unique benefits, depending on the scale, material, and complexity. This gives designers several options to turn digital ideas into real, functional objects.

In the end, combining parametric design with various manufacturing techniques helps designers work faster, experiment more freely, and create complex or customized forms efficiently. BeeGraphy shows how computational design can move from software into the physical world, providing a flexible workflow that connects creativity with functionality.

Check out the latest fabricator update in Beegraphy here