Table of Contents

The design and construction industry is grappling with a paradox: while BIM (Building Information Modeling)promised a unified, data-rich model for every project, the reality is often a series of frustrating failures. The challenge isn’t creating the model; it’s moving the data—especially complex geometry and associated specifications—reliably between architects, engineers, fabricators, and contractors.

This inefficient, file-based exchange, where critical information is lost or corrupted in translation, drains billions from the sector annually. The key to solving this is not a new file format, but a new data infrastructure. The future of reliable AEC Data Hand-Off lies in adopting Cloud-Based Parametrics as the single source of project truth.This inefficient, file-based exchange, where critical information is lost or corrupted in translation, drains billions from the sector annually. The key to solving this is not a new file format, but a new data infrastructure. The future of reliable AEC Data Hand-Off lies in adopting Cloud-Based Parametrics as the single source of project truth.

(See: McKinsey & Company, “The Next Normal in Construction” (2020), p. 8, which identifies fragmented data and lack of interoperability as major causes of inefficiency and rework across the global construction value chain.)

The Interoperability Nightmare: The Price of File Isolation

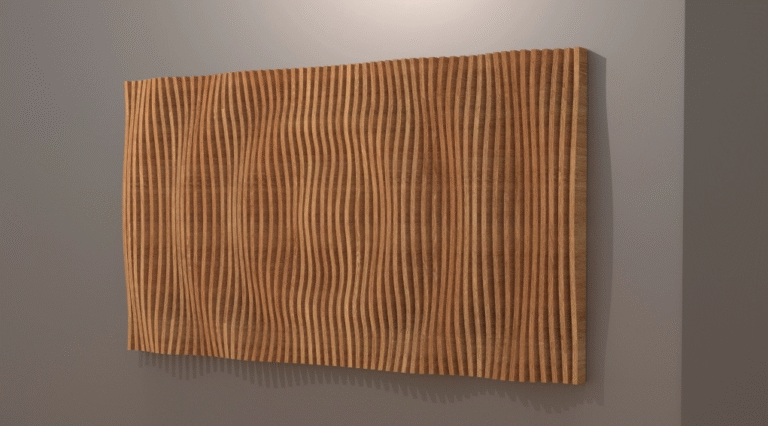

Consider a typical scenario involving a complex, custom-designed element, such as a signature facade or a geometrically unique space-frame roof.

When the lead design team finalizes the geometry in their desktop BIM application, the AEC Data Hand-Off begins. The resulting file is often massive, software-specific, and immediately hits a wall of interoperability:

- Loss of Fidelity: Exporting the model via an industry standard like IFC often simplifies complex, non-standard geometry, turning precise design intent into generic, unreliable meshes.

- Version Control Chaos: Every time the engineer tweaks a structural element or the cost consultant updates material specifications, the designer must manually import the revision, verify the changes, and re-export a new version. This sequential, localized process makes simultaneous collaboration impossible and guarantees errors.

This struggle highlights a fundamental flaw: the project data is locked within heavy, static file silos on individual desktops, impeding BIM Interoperability.

Live Data Streams: The Alternative to Static Files

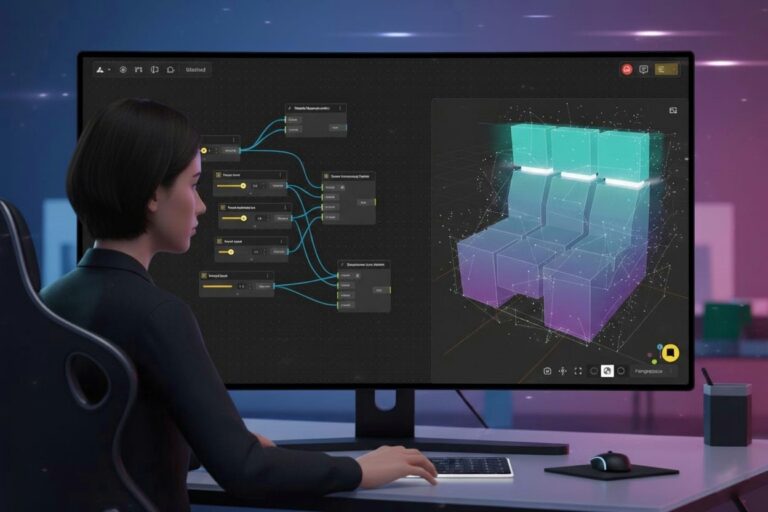

Instead of exchanging static file bundles, a Cloud-Based Parametric platform treats the project as a live data stream. The core design logic is hosted on a secure central server. Design teams, structural engineers, and fabricators don’t download files; they access the same living model, pulling only the specific data parameters they need in real time.

This ensures that any change made by the architect is instantly available and correctly calculated for the fabricator, eliminating data loss and version control headaches.

Creating the Truly Digital Twin: Data as a Carrier

In a cloud-based parametric environment, the data-rich model becomes a true Digital Twin for AEC. Every component is not merely a visual representation but a robust data carrier whose properties and relationships are defined by its underlying script.Imagine a large, custom perforated ceiling panel. The parametric model understands its structural dependencies, its material type, its exact quantity, and its required toolpath.

Instant, Tailored Data for Every Stakeholder

The power of a single cloud-based source of truth is its ability to instantly generate tailored data outputs on demand. This flexibility transforms the final stages of the AEC Data Hand-Off:

- For the Cost Estimator: The platform instantly runs a script to calculate the exact material surface area and quantity of fasteners, providing a real-time, accurate cost breakdown. (This kind of dynamic calculation is also key to efficient workflow:

- For the Fabricator: The system flattens the 3D geometry and auto-generates precise, error-free 2D files (like DXF) or machine instructions (G-code) for immediate fabrication.

- For Facility Management: The model retains all design and material parameters, making it an invaluable asset for long-term maintenance and future renovations.

This ensures that the innovation of the design team seamlessly translates into the efficiency required by the construction and manufacturing teams. The data remains consistent, accurate, and instantly accessible to everyone across the project lifecycle. (For a deeper understanding of Digital Twins in construction, explore: Link to Digital Twin in AEC resource, e.g., IBM/Siemens AEC Digital Twin Whitepaper)

How BeeGraphy Bridges the AEC Data Hand-Off Divide

The transition from the traditional desktop file-exchange chaos to a seamless cloud workflow is built on key technical features that eliminate data friction. BeeGraphy offers these fundamental advantages by serving as the project’s central parametric engine:

Feature-Driven Value in Data Hand-Off

- Cloud-Hosted Logic, Not Heavy Files: Unlike traditional BIM and CAD where design logic and relations are locked inside massive, versioned files, BeeGraphy hosts the computational design logic securely in the cloud. This means stakeholders are always accessing the latest, single source of truth, eliminating the need to download or manage heavyweight software or proprietary files. (BeeGraphy editor overview)

- Precise, On-Demand Data Query: The platform allows you to query and export precisely what downstream users need. A structural engineer can pull raw coordinates, the cost estimator can pull metadata for material properties, and the fabricator can pull output files—all from the same live model. This prevents the costly, all-or-nothing data dumps typical of desktop exports.

- Real-Time, Collaborative Interaction: Designers, fabricators, and engineers can interact with and contribute to the same live parametric model simultaneously. This drastically minimizes data loss and translation errors, ensuring that design intent remains intact throughout the entire project lifecycle.

- Reusable Logic through API and Marketplace: BeeGraphy’s API layer (and/or its potential Marketplace) BeeGraphy’s API lays the foundation for sharing and reuse of parametric logic modules across projects. As the Marketplace evolves, we will support validated computational libraries that streamline design workflows. (Beegraphy API)

- A Project-Wide Source of Truth: Over time, the centralized cloud model becomes the undisputed project-wide source of truth. This singular point of reference radically reduces file exchanges, eliminates version conflicts and data corruption, and minimizes the re-work traditionally associated with AEC Data Hand-Off.

Conclusion: The Cloud Revolution in AEC Collaboration

The AEC industry’s pursuit of BIM efficiency is being unlocked by Cloud-Based Parametrics. By migrating the core design logic from isolated desktop files to a dynamic, collaborative cloud server, platforms like BeeGraphy solve the critical problem of the AEC Data Hand-Off.

The next wave of project efficiency lies in this transition—from the pain of static file exports to the power of a single, live data stream. Embracing this cloud revolution means less time spent reconciling data and more time building.