Table of Contents

What if every furniture customization took minutes instead of hours without compromising quality?

For many small workshops, even a tiny design tweak can throw off an entire workflow. Change the width of a table, swap the material, or resize a drawer, and suddenly you’re redrawing files, recalculating joints, and re-exporting cut layouts, all while hoping you didn’t miss something.

Now imagine doing that several times a week, or even per day. Without a configurator.

To understand just how much time and energy this costs, let’s consider a hypothetical example.

Meet Alex – a stand-in for thousands of skilled furniture makers facing this challenge daily. Alex runs a small but thriving furniture workshop with a team of six skilled craftsmen and a CNC laser cutter. His specialty? Mid-century modern pieces made from sustainably sourced wood. Clean lines, smooth finishes, and the occasional custom request.

One day, a customer walks into the workshop, falls in love with one of Alex’s coffee tables, and asks, ‘Can you make this just a little longer, and in walnut instead of oak?’

Alex smiles and says yes… but inside, he knows what’s coming. Another two hours spent tweaking the 3D model, generating new cut files, adjusting for material differences, and hoping nothing slips through the cracks.

There has to be a better way out, right?

That’s where Parametric Design comes in.

What Exactly Is Parametric Design?

For furniture makers like Alex, the real problem isn’t the customization… It’s the manual work that follows. Every tweak requires time, precision, and repetition. But what if your designs could adjust themselves?

That’s the promise of parametric design.

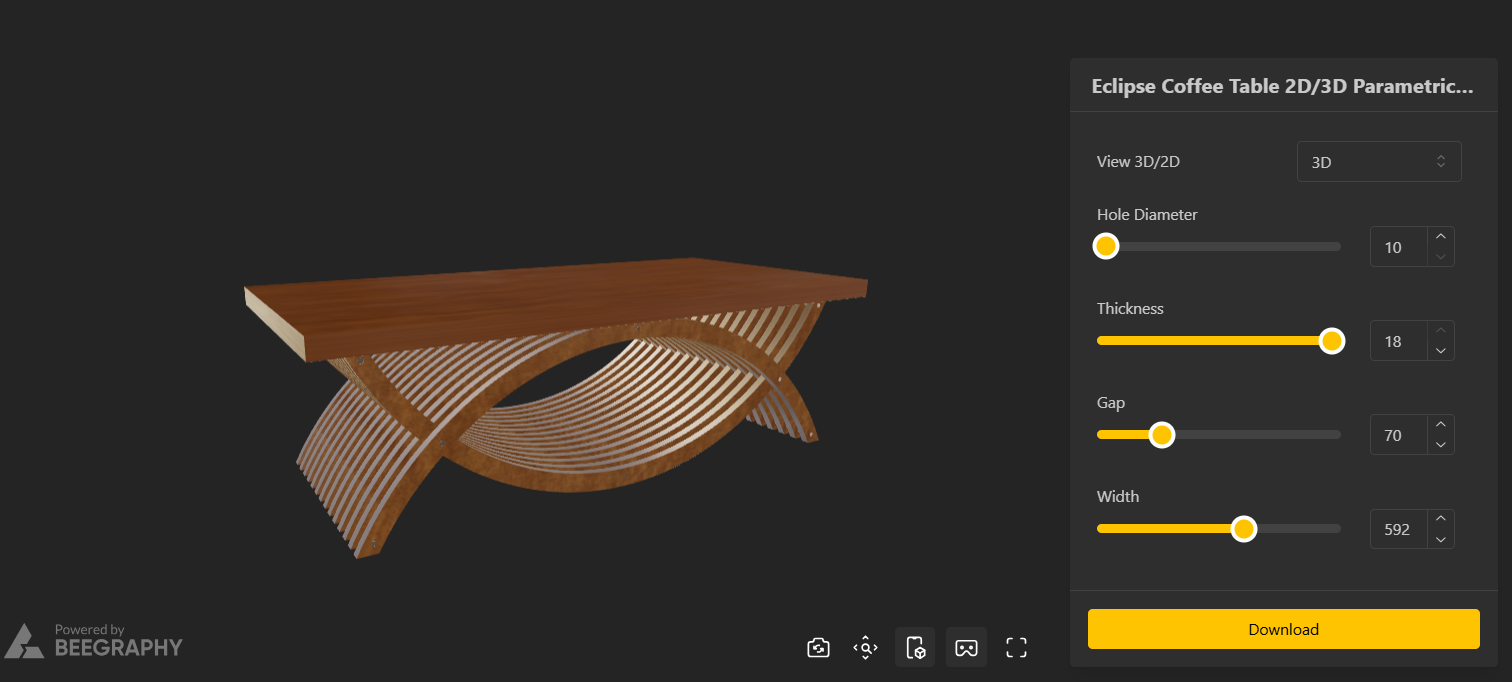

At its core, parametric design is a rule-based approach to modeling. Instead of building fixed, one-off designs, you create smart, dynamic models paired with configurators, where every part (length, height, joints, even curves) is driven by parameters: numbers, relationships, or user inputs.

Change the tabletop length? The legs adjust automatically. Switch the wood thickness? The joinery adapts to fit. You’re no longer just drawing, you’re building a responsive design system.

Thanks to tools like BeeGraphy, this approach is now accessible to small and mid-sized workshops, right from the browser. No expensive CAD licenses, no advanced scripting skills. Just logic, design, and a bit of curiosity. For building your own configurable models, you can check out Configurator.tech powered by BeeGraphy.

Configurator.tech by BeeGraphy

How Parametric Design Streamlines Furniture Workflows

So what happened when Alex actually put parametric design to work? Before, customizing a single coffee table meant going through the same manual routine every time:

Manually tweak the 3D model

↓

Adjust joinery and material tolerances

↓

Regenerate laser/CNC cut files

↓

Double-check everything before exporting

Total time? Nearly 2 hours per variation.

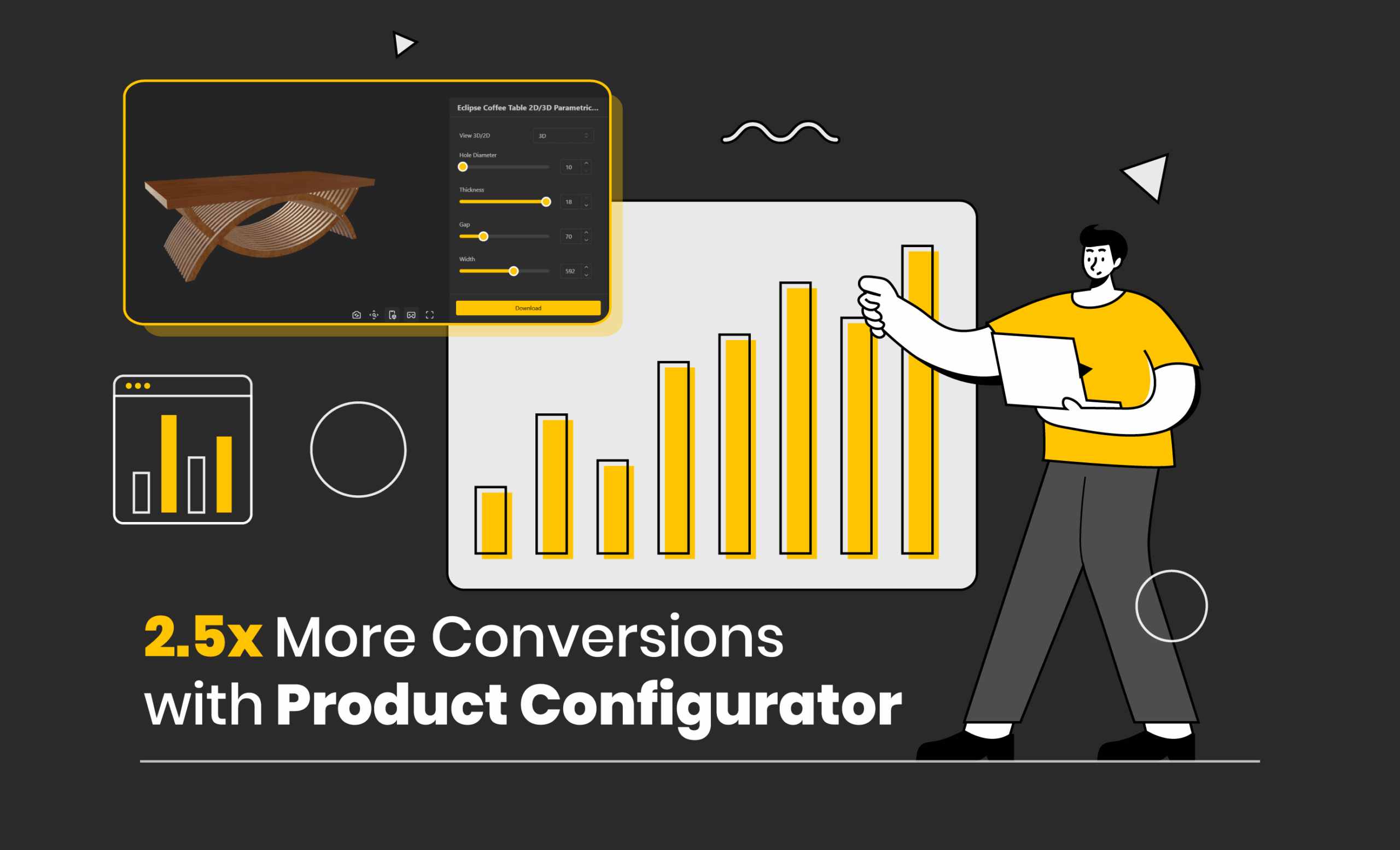

But after switching to a product configurator, Alex cut that down to just 15 minutes. One design file. Infinite flexibility.

Here’s what made the difference:

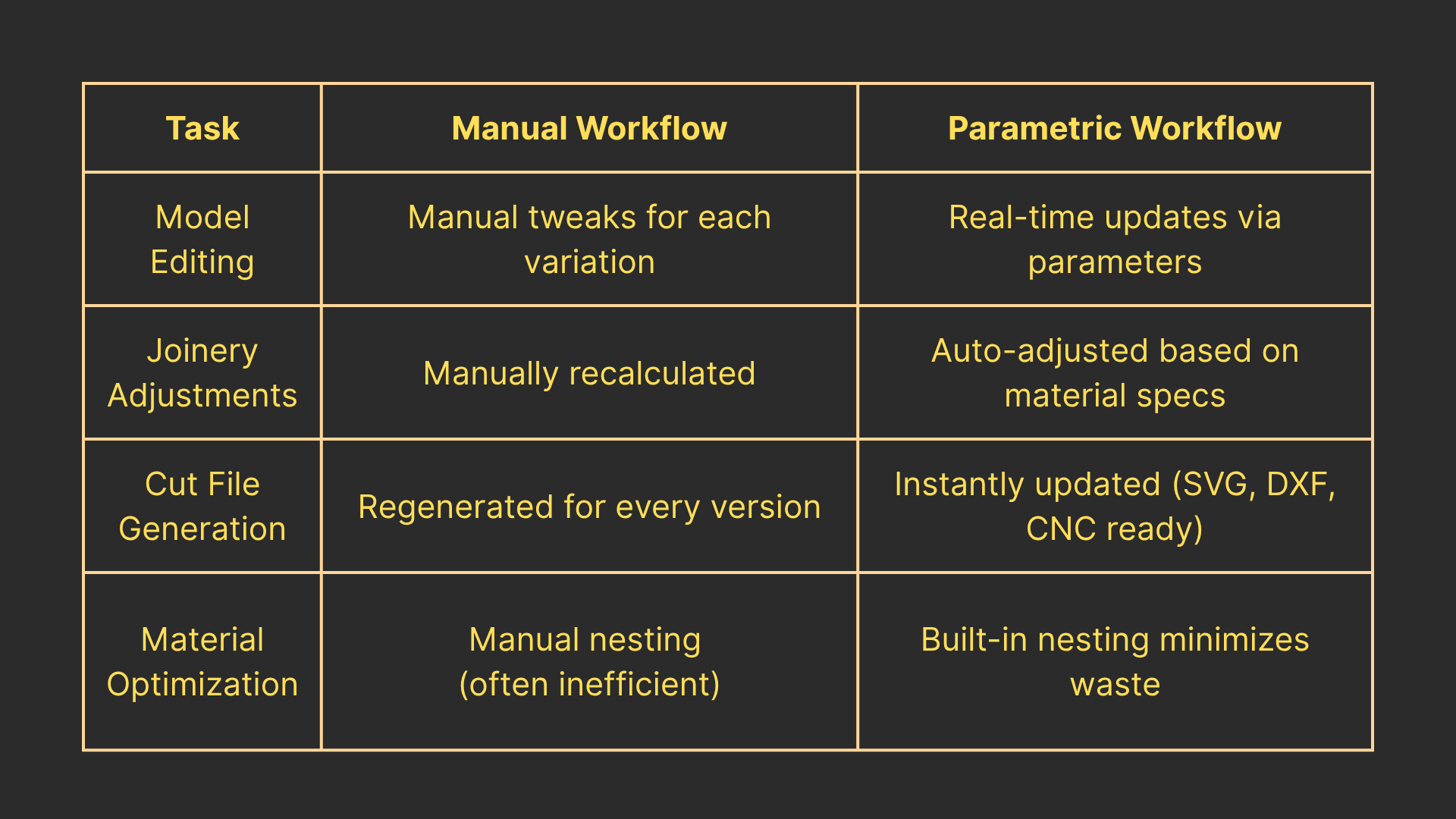

Automated File Generation

Once a parametric model is set up with the configurator, every change updates the entire design automatically. That includes cut files (SVG, DXF) or even CNC-ready instructions.

No More Repetitive Work

In the past, Alex’s team had to remake each product variation from scratch. Now, with parametric configurator templates, they design once and generate dozens of custom versions in minutes.

Smarter Material Use

Because parametric models can include material logic, parts are automatically sized to fit standard boards and optimized for minimal waste. Built-in nesting doesn’t just save time. It also helps reduce material waste, which is especially useful when working with plywood or MDF sheets.

Less Back-and-Forth with Production

By locking key parameters, like board thickness or joinery types, Alex ensures his workshop team doesn’t need to interpret vague design notes or risk errors. The logic is baked into the model, so there’s less explanation, fewer mistakes, and faster hand-offs between design and production.

Manual Workflow vs. Parametric Workflow

How Furniture Makers Use Parametric Design

As Alex refined his parametric workflow, he quickly realized he wasn’t just solving one problem, he was unlocking a smarter, more scalable way of doing business. What began as a time-saving method for one coffee table evolved into a streamlined system for his entire product line.

Today, product configurators are reshaping the way furniture makers design, sell, and produce, from custom shelving systems to flat-pack furniture. And the numbers speak for themselves:

Consumers Are Willing to Pay More for Customization

According to research by Cylindo, 76% of consumers are willing to pay more for products they’ve configured themselves. This phenomenon, often referred to as the IKEA Effect, gives customers a sense of ownership and emotional connection to the product, leading to higher satisfaction and brand loyalty.

Tested Results from B+N Industries

When B+N Industries, a modular shelving manufacturer adopted a web-based furniture configurator, they achieved:

- 30% more customer inquiries

- 50% faster quote-to-order cycles

- 18% higher proposal win rates

These numbers highlight how configurators not only improve customer experience but also speed up internal processes and increase conversions.

But What about the Craft?

‘If I automate the design process… will my work lose its soul?’

It’s a fair concern. After all, the charm of handcrafted furniture lies in its detail, its imperfections, and the story it tells. But here’s the truth: parametric design doesn’t replace your craftsmanship; it enhances it.

Think of it as a supercharged pencil. You’re still the designer. You’re still making the creative decisions. You’re just working faster, more precisely, and with fewer mistakes to fix later.

Tip: Use parametric logic to handle the technical side (i.e. dimensions, joint tolerances, cut layouts). Then add your signature by hand: unique textures, finishes, edge treatments, or custom engraving. That’s where your brand’s soul lives.

New to Parametric Design? Here’s How to Begin.

Here’s how even small furniture studios can begin with parametric design:

1. Pick a Product

Start with something commonly customized — like a stool, nightstand, or coffee table.

2. Define the Parameters

Decide what can change: height, width, depth, material thickness, etc.

3. Build the Model

Use the BeeGraphy Editor for browser-based modeling, and Configurator.tech for product configuration. No installs, no complex setup.

4. Test Internally

Run test orders through the model. Compare the time saved versus traditional workflows.

5. Create a Template Library

Over time, build a collection of your best-selling models as parametric templates: reusable, editable, and production-ready.

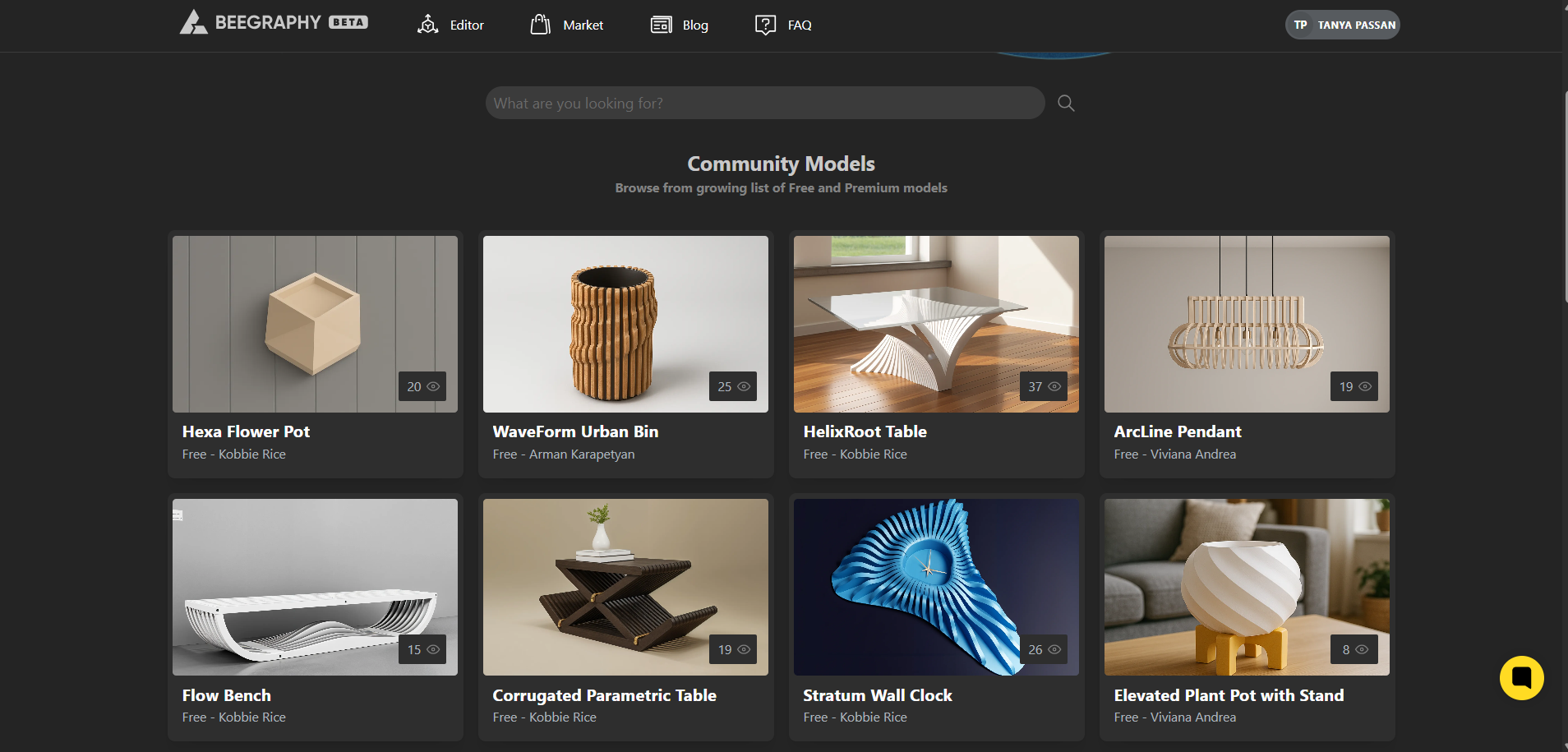

Explore BeeGraphy Marketplace

Why Product Configurators are the Smartest Upgrade for Your Furniture Workflow

For Alex, adopting parametric design wasn’t about going ‘fully digital’. It was about working smarter, responding faster, and maintaining quality at scale.

Whether you’re a solo craftsman, a small studio, or a growing manufacturer, product configurators like Configurator.tech powered by BeeGraphy helps you save time, reduce errors, and expand your offering without adding overhead.

You don’t need to change how you build.

Just change how you design.

Start small. Stay curious. And before long, you’ll wonder how you ever worked without it.