Table of Contents

Custom manufacturing is redefining how products are designed, produced, and delivered. In 2025, personalization is no longer optional , it’s a customer expectation. Consumers today want unique products: furniture crafted to fit their exact spaces, jewelry tailored to their style, or medical implants designed exclusively for their bodies.

To meet this rising demand, manufacturers are turning to advanced technologies like 3D printing, parametric design, CNC automation, IoT, and AI-driven product configurators. These tools make it possible to offer personalization at scale without slowing down production or driving up costs.

According to Verified Market Research, the custom manufacturing market is projected to grow from USD 939.7 billion in 2024 to USD 1,287.4 billion by 2030, proving that customization is shaping the future of the manufacturing industry.

In this blog, we’ll explore the most significant trends and technologies in custom manufacturing and show how BeeGraphy is helping businesses adapt and thrive.

Why Custom Manufacturing Matters Today

Traditional manufacturing revolved around mass production: producing thousands of identical products to minimize costs but in today’s world, that approach no longer works. Consumers now want products tailored to their identity, lifestyle, and space.

Imagine shopping for a dining table online. A decade ago, you had to choose from fixed sizes and colors, even if they didn’t fit your home perfectly. Now, customers expect the option to customize dimensions, finishes, and designs and still receive their product without delay.

This shift has made custom manufacturing technologies essential for staying competitive. Manufacturers that fail to adapt risk being left behind by more agile, customer-centric businesses.

Key Trends Driving Custom Manufacturing in 2025

Mass Customization at Scale

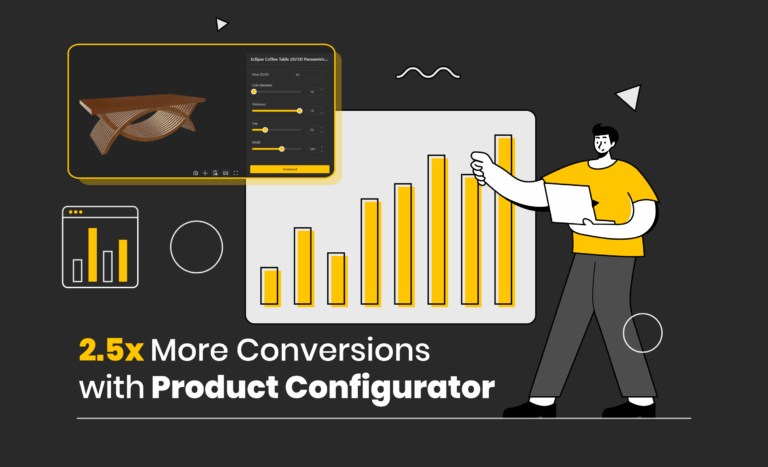

For years, custom products meant higher costs and long delivery timelines. But advances in digital design tools and automation have changed the game. Today, manufacturers can achieve mass customization combining personalization with production efficiency.

BeeGraphy’s product configurator makes this seamless. Customers can personalize products directly on a business’s website, selecting dimensions, materials, patterns, and finishes in real time. Once finalized, the system instantly generates CNC- and laser-ready files along with accurate price quotations, sending everything to the manufacturer.

This workflow eliminates manual CAD redesigns, long quoting cycles, and endless email threads. Businesses can now handle hundreds of unique designs simultaneously, delivering personalized products at the speed of mass production.

Sustainability Through On-Demand Manufacturing

Sustainability isn’t just a trend ,it’s becoming a requirement. Consumers are more eco-conscious than ever, and governments are tightening regulations around waste and emissions.

Custom manufacturing naturally supports sustainable production. Instead of creating products in bulk and risking overstock, businesses now adopt on-demand models. Products are manufactured only when ordered, reducing waste and optimizing storage.

BeeGraphy’s parametric design platform takes this a step further by optimizing material usage for every design variation by minimizing cut-offs and scraps, manufacturers can reduce environmental impact while maintaining profitability.

Localized Micro-Factories and Faster Delivery

Speed matters. Customers expect custom products quickly, and manufacturers are responding by moving away from centralized production toward localized micro-factories.

Instead of relying on a single large plant, businesses now operate regional hubs closer to customers. This not only reduces shipping costs and lead times but also improves the flexibility of personalized production.

When paired with tools like BeeGraphy’s configurator, this becomes even more efficient. A customer can customize a design online, and the fabrication-ready files can be sent directly to a nearby production partner. The result is faster delivery, lower costs, and higher customer satisfaction.

Technologies Shaping the Future of Custom Manufacturing

3D Printing / Additive Manufacturing

3D printing has revolutionized prototyping and small-batch production. Manufacturers can now create complex, highly customized designs without the need for traditional molds or tooling.

Industries like medical devices, aerospace, jewelry, and furniture are leading the adoption of this technology, delivering personalized products faster and at lower costs.

Watch this YouTube video to see how 3D printing is reshaping manufacturing.

CNC and Laser Automation

CNC machines and laser cutters are staples of modern manufacturing, but their integration with parametric design tools has unlocked new capabilities.

Instead of manually adjusting CAD files for every product variant, Tools like BeeGraphy automatically generates fabrication-ready CNC and laser files. This saves design labor, reduces human error, and accelerates delivery timelines which is critical advantages in the custom manufacturing space.

IoT-Powered Smart Factories

The Internet of Things (IoT) is turning traditional factories into intelligent production systems.

Sensors now monitor machine health, energy consumption, and real-time performance, enabling predictive maintenance and reducing downtime. This is especially valuable in customized production environments, where workflows are more complex and require greater control.

Artificial Intelligence and Predictive Analytics

AI is enabling manufacturers to predict demand, optimize production schedules, and automate pricing for customized products.

BeeGraphy leverages AI within its real-time configurator to calculate accurate prices instantly, no matter how complex the product. Manufacturers save hours of manual work while customers get a smooth, transparent experience.

Parametric Design Platforms: BeeGraphy’s Edge

Parametric design lies at the heart of modern custom manufacturing. BeeGraphy’s cloud-based platform lets designers build algorithm-driven 3D models where dimensions, forms, and materials are fully customizable.

When a customer personalizes a design — adjusting size, finishes, or patterns — BeeGraphy automatically updates the 3D preview, recalculates pricing, and generates production-ready files.

Watch this YouTube demo to see how parametric design is redefining customization.

How BeeGraphy is leading the Change

BeeGraphy isn’t just a modeling tool — it’s an end-to-end ecosystem for custom manufacturing.

-

Designers create dynamic, customizable 3D models in a browser.

-

Manufacturers receive instant CNC, laser, or 3D-printing files for each order.

-

Businesses offer customers an interactive configurator, complete with real-time previews and pricing.

By bridging the gap between customer creativity and manufacturing precision, BeeGraphy enables businesses to deliver personalized products at scale.

Explore the platform here and discover how BeeGraphy is shaping the future of custom manufacturing.

Conclusion

The future of manufacturing is personal, sustainable, and digital-first. Customers expect products designed specifically for them, and businesses must adapt to meet this demand.

Technologies like 3D printing, CNC automation, IoT, AI, and parametric design platforms are transforming how manufacturers create, customize, and deliver products. Platforms like BeeGraphy make these innovations accessible, empowering businesses to scale personalization without sacrificing efficiency.

Companies that embrace these trends and technologies today will define the future of custom manufacturing tomorrow.