Table of Contents

When it comes to digital fabrication, the file format you choose is just as important as the design itself. It acts as a digital blueprint, telling your machine, whether that’s a 3D printer, CNC router, or laser cutter, exactly how to bring your idea to life. Pick the wrong one, and you might end up with scaling errors, missing details, or even a failed print. Pick the right one, and the process flows smoothly from screen to reality.

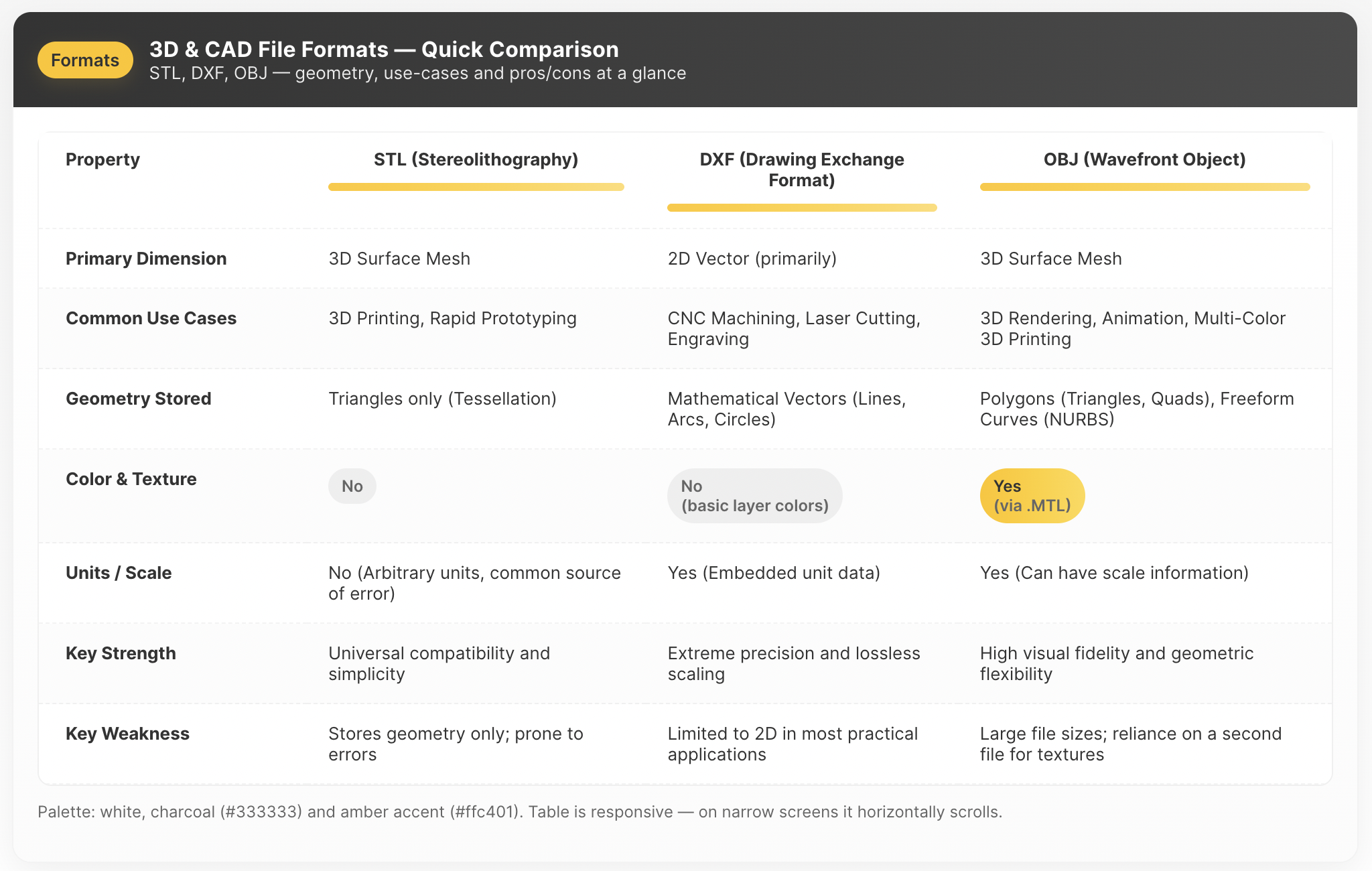

So, what’s the difference between the most common file formats, STL, DXF, and OBJ?

- STL is the universal language of 3D printing. It describes surface geometry using triangles and works with nearly every 3D printer and slicer on the market.

- DXF is the precision tool for 2D fabrication. Used in laser cutting, CNC routing, and engraving, it stores exact vector paths for clean, accurate cuts.

- OBJ is the artist’s choice. It goes beyond geometry to capture color, textures, and detail, making it popular for rendering, animation, and full-color 3D printing.

In short: STL = 3D printing, DXF = 2D cutting, OBJ = 3D detail and textures.

This blog will break down what makes each format unique, when to use them, and the pros and cons you should know as a maker.

Finally, we’ll show you how BeeGraphy, a browser-based parametric design platform, makes it easier to create, manage, and export designs into these formats for fabrication or sharing. By the end, you’ll have a clear roadmap for choosing the right file format every time.

2. What Are STL, DXF, and OBJ Files?

2.1 What Is an STL File?

The STL file format (short for stereolithography or sometimes standard tessellation language) is the most common 3D printing file format. First developed in 1987, it has become the de facto standard for additive manufacturing.

An STL represents a 3D object as a mesh of tiny triangles (a process called tessellation). The more triangles, the smoother the surface appears; fewer triangles mean smaller files but visible “faceting.” STL files come in two flavors: ASCII (human-readable but large in size) and binary (compact and widely used).

Primary Uses:

- Universal format for 3D printing and rapid prototyping

- Compatible with almost all slicers and 3D printers

Pros:

- Universally supported across hardware and software

- Lightweight and quick to process (in binary form)

- Simple surface geometry, easy for slicers to interpret

Cons:

- No color, texture, or material data (geometry only)

- Doesn’t store units (risk of scaling errors)

- Difficult to edit once tessellated into triangles

- Can have mesh errors like gaps or holes if not exported properly

When to use STL: For standard single-color 3D printing, prototypes, and designs where surface geometry is all that matters.

2.2 What Is a DXF File?

DXF (Drawing Exchange Format) was created by Autodesk in 1982 as a universal way to share CAD drawings. Unlike STL, which uses meshes, DXF is vector-based, it represents shapes using precise mathematical paths (lines, arcs, and curves). This makes DXF ideal for 2D fabrication workflows.

Primary Uses:

- Laser cutting and engraving

- CNC milling and routing

- Technical drawings, floor plans, and schematics

Pros:

- Extreme precision (stores accurate vector paths)

- Scales infinitely without losing quality

- Includes unit data (avoids scaling issues)

- Supported across most CAD/CAM platforms

Cons:

- Mostly limited to 2D workflows (3D DXF is rare and poorly supported)

- Not directly usable for 3D printing without conversion

- Large file sizes for complex designs

When to use DXF: For laser cutting, CNC machining, or any fabrication that requires 2D outlines and accuracy.

2.3 What Is an OBJ File?

The OBJ file format was originally developed by Wavefront Technologies for 3D graphics and animation. Unlike STL, it supports polygons beyond triangles and can handle textures, colors, and material properties through a companion MTL (material library) file.

This makes OBJ ideal not just for fabrication, but also for visual applications like rendering, gaming, AR/VR, and full-color 3D printing.

Primary Uses:

- 3D modeling for visualizations, games, and animations

- Detailed 3D printing with colors/textures

- Web-based 3D viewers and AR/VR

Pros:

- Supports colors, textures, and materials (via MTL)

- Can use quads and NURBS for smoother geometry

- Compatible with most 3D modeling software

- Can store multiple objects in one file

Cons:

- Larger file sizes than STL (slower to process)

- Requires MTL and texture files for full fidelity (easy to misplace)

- Doesn’t support animations (geometry only)

- Considered somewhat outdated compared to modern formats like glTF

When to use OBJ: For detailed 3D models with textures, web visualization, AR/VR, or full-color 3D printing.

Quick comparison of STL, DXF, and OBJ file formats.

3D File Formats for the Web

When moving from physical fabrication to digital display, the priorities of a file format change. Instead of focusing only on machine compatibility and geometric accuracy, web-based formats need to balance file size, rendering speed, and interactivity.

Is OBJ good for web 3D?

The OBJ format has long been used for online visualization because it can store textures and colors via MTL files. But OBJ is large and text-based, which makes it slow to load, especially on mobile devices or in AR/VR.

What is glTF and why is it called “the JPEG of 3D”?

To overcome OBJ’s limitations, the glTF (GL Transmission Format) was created. It’s often called the “JPEG of 3D” because it’s optimized for fast web delivery.

Benefits of glTF:

- Compact and lightweight (.glb version especially)

- Supports realistic lighting and PBR materials

- Includes animations and interactivity

- Widely used in e-commerce, AR, and VR

For web-based 3D and AR, glTF has become the new standard.

How BeeGraphy Helps with STL, DXF, and OBJ Files

Understanding file formats is one thing, working with them efficiently is another. That’s where BeeGraphy, a cloud-based parametric design platform, comes in.

- STL support: Export designs directly for 3D printing, optimized for resolution and file size.

- DXF support: Generate accurate toolpaths for CNC machining or laser cutting. Parametric updates ensure instant adjustments without redrawing.

- OBJ support: Export models for rendering, AR/VR, or multi-color 3D printing, with marketplace integration for selling files.

Why BeeGraphy stands out:

- Browser-based, no installation needed.

- Parametric modeling, change one parameter, update the whole model.

- Multi-format exports, STL, DXF, OBJ from a single design.

- Marketplace, sell ready-to-use models to other makers.

- Collaboration, share and co-create in real time.

In short, BeeGraphy helps makers design once and export everywhere.

Design in BeeGraphy and export in STL, DXF, or OBJ — ready for printing, cutting, or rendering

Choosing the Right File Format Every Time

There isn’t a single “best” 3D file format, it all depends on what you’re trying to achieve.

- STL is the workhorse for 3D printing.

- DXF is the precision tool for CNC and laser cutting.

- OBJ is the artist’s choice for textures, colors, and visualization.

By mastering these formats, you’ll avoid costly mistakes and move seamlessly from digital design to physical creation.

And with BeeGraphy, you don’t need to juggle different tools or workflows. You can design parametrically once, then export to STL, DXF, or OBJ depending on your project, making it faster, easier, and more reliable to bring your ideas to life.

Bottom line: Choosing the right file format is step one. Using BeeGraphy to manage them is step two. Together, they make the path from screen to reality smoother than ever.

Frequently Asked Questions on 3D File Formats

What file format is used for 3D printing?

The most common 3D printing file format is STL. Nearly every 3D printer and slicer supports it, making it the safest choice. If your printer supports multi-color or multi-material printing, you can also use OBJ or newer formats like 3MF.

What are the different files for 3D printing?

Beyond STL, makers often use:

- OBJ → For textured or multi-color prints (requires an MTL + texture files).

- AMF (Additive Manufacturing File) → Stores colors, materials, and curved geometry.

- 3MF (3D Manufacturing Format) → A modern format designed to replace STL, bundling all geometry, colors, and even print settings.

Still, STL dominates because of its universal support across printers and software.

What is STL and OBJ in 3D printing?

- STL: Geometry-only file, best for standard 3D printing. Lightweight, universally compatible.

- OBJ: Stores geometry + textures/colors via MTL, best for color 3D printing or rendering.

What is the most common 3D file format?

STL is the industry standard and has been since the late 1980s. Its simplicity and widespread support give it a powerful network effect—every slicer, printer, and repository supports STL files.

What are the different types of file formats for 3D printing (free)?

Most free CAD and modeling tools let you export:

- STL (default for 3D printing)

- OBJ (for textured/colored models)

- 3MF (modern alternative, free in tools like Fusion 360, Blender, and Tinkercad)

How to create STL files for 3D printing?

- Model your design in software like Fusion 360, Blender, Tinkercad, or SolidWorks.

- Go to File > Export or Save As.

- Choose STL (.stl) as the output format.

- Select Binary (smaller and faster than ASCII).

- Adjust resolution/tolerance for balance between file size and smoothness.

- Slice and print with software like Cura or PrusaSlicer.