Table of Contents

In 2017, Adidas introduced something that caught the attention of designers, engineers, and athletes alike: the Futurecraft 4D sneaker. Unlike traditional footwear, this sneaker had a 3D-printed midsole with a visually complex lattice structure. It didn’t come from a sketchbook. It was generated using performance data, algorithms, and a manufacturing process called Digital Light Synthesis.

At the time, the shoe felt like a prototype from the future. But in reality, it signaled the start of a new design era: one that is already taking shape.

The Shift from Handcrafting to Data-Driven Design

Traditional footwear design relied on hand sketches, physical prototypes, and fixed molds. Even with CAD tools, making changes often meant starting over. Parametric design transforms this process.

Instead of modeling everything manually, it uses rule-based workflows that involve changes to inputs like foot dimensions or sole thickness that automatically update the entire design. This approach has been particularly effective for specific components. For instance, researchers have built parametric shoe last models (3D foot-shaped forms used to build shoes) from 3D scans, allowing designers to tweak heel height or toe box shape without compromising fit (L. Chertenko et al., 2022).

Midsole lattices, vital for cushioning, can also be generated via parametric rules, optimizing impact response, as seen in Adidas’s 4D midsoles created with Carbon’s Digital Light Synthesis. By enabling faster iterations and mass customization, parametric modeling supports performance, personalization, and speed, key demands in modern sportswear design.

Adidas Futurecraft 4D

What is Parametric Design and Why Does It Matter in Footwear?

Parametric design is a method where geometry is generated using adjustable parameters. Designers define the logic of a design, and then fine-tune that logic by entering different values. Instead of building each version manually, the system handles the variations.

For footwear, this is especially powerful. Every sport demands different support. And every athlete, whether amateur or professional, has specific needs. Athlete or not, every foot is different. Parametric design allows designers and brands to build shoes that are naturally adaptable to any size or form by letting the customers build a custom size for themselves.

Why Footwear is a Natural Fit for Parametric Thinking

Footwear must balance form and function: it needs to be breathable, durable, lightweight, and support movement while absorbing shock and expressing the brand identity. Parametric design adds flexibility to this complex process, enabling designers to create adaptable models without starting from scratch. Here’s how that’s already happening.

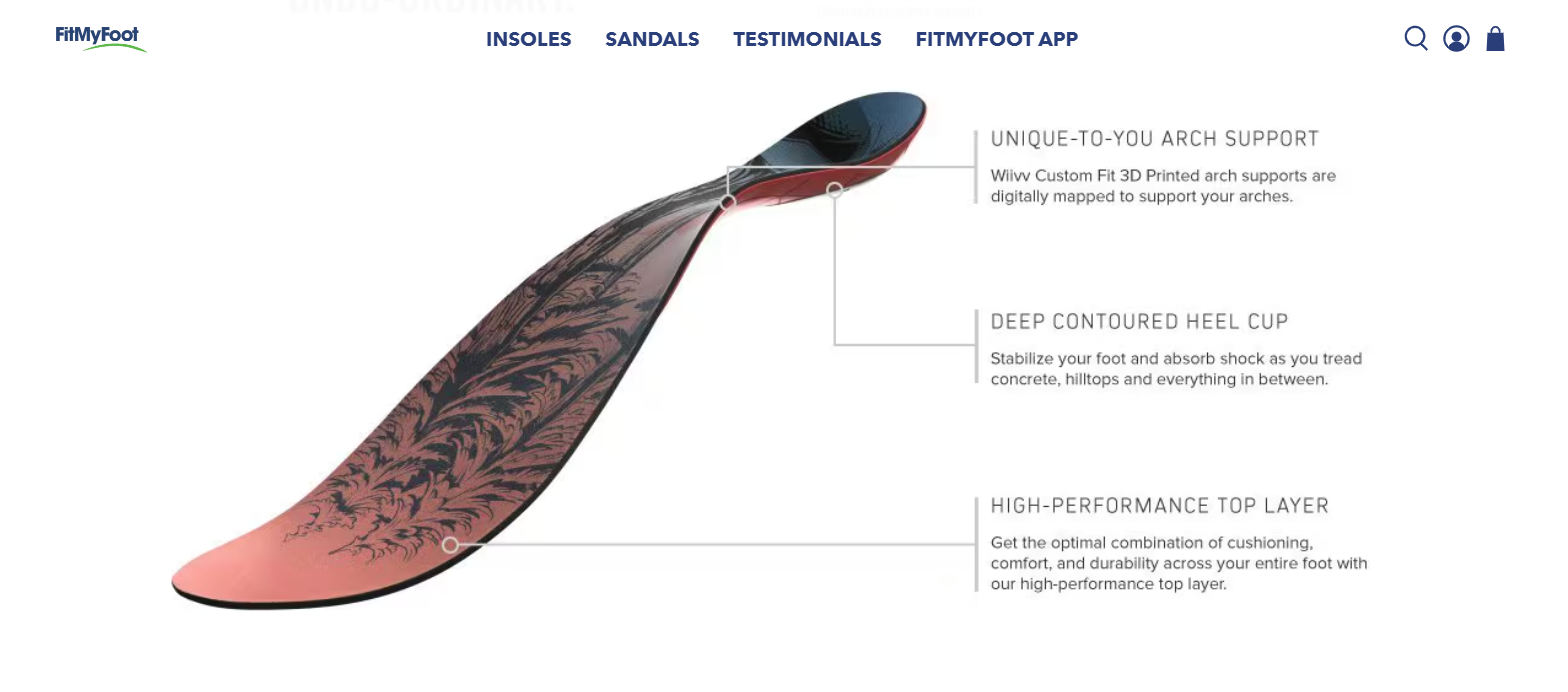

1. Fit Customization with FitMyFoot

FitMyFoot creates custom insoles and sandals created using 3D foot scans via its mobile app. Users take a few guided photos of their bare feet on paper, and the app captures 200+ data points across the arch and heel to generate a precise digital model.

Instead of manual design, a parametric backend adjusts a base template to customize arch support, heel cup shape, and pressure distribution. The result: consistent manufacturing quality, a personalized fit, and doorstep delivery in about a week.

Custom Insoles by FitMyFoot

2. Performance Optimization with Adidas Futurecraft 4D

The Adidas Futurecraft 4D stands out as one of the most well-known applications of parametric design in the sportswear industry. Using data from thousands of athletes, Adidas and Carbon created midsoles with lattices engineered for targeted cushioning and energy return, denser in the heel for impact absorption and lighter in the forefoot for rebound. This structural precision was possible only through a parametric model and programmable 3D printing. After debuting in 2017, the series evolved with the AlphaEDGE in 2018 and 4DFWD in 2021. These innovations show how parametric design can transform not just shoe production, but athletic performance and personalization.

Midsole Design for Adidas Futurecraft 4D

3. Fast Prototyping with Under Armour Architech

Under Armour’s Architech series showcased how parametric and generative design could drastically accelerate product development. Its distinctive lattice midsoles, developed with Autodesk Within software and 3D printed via selective laser sintering (SLS) at their Baltimore Innovation Lab, enabled rapid design iteration.

The generatively-designed midsole geometry was ideal for 3D printing and included zones optimized for cushioning, flexibility, and stability. The process involved over two years of R&D and mechanical testing, more than 120 hours of physical testing and feedback from over 80 athletes, before launching just 96 limited pairs in March 2017.

Architech by Under Armour

Parametric design isn’t just for global giants. Independent innovators are pushing boundaries too. Companies like Zellerfeld use parametric files to produce fully 3D-printed, recyclable, made-to-order sneakers, collaborating with designers to bypass inventory and tooling. Similarly, Czech designer Lucie Trejtnarová explores fluid mesh footwear that moves with the body, highlighting the expressive potential of generative modeling. These cases show that parametric design is accessible to anyone willing to experiment.

From Labs to Laptops: The Future of Footwear Design

What began with innovations like Adidas Futurecraft 4D, a shoe generated from data, not drawn by hand, has grown into a broader design shift. Parametric tools once exclusive to billion-dollar labs are now accessible to anyone with a laptop and internet connection.

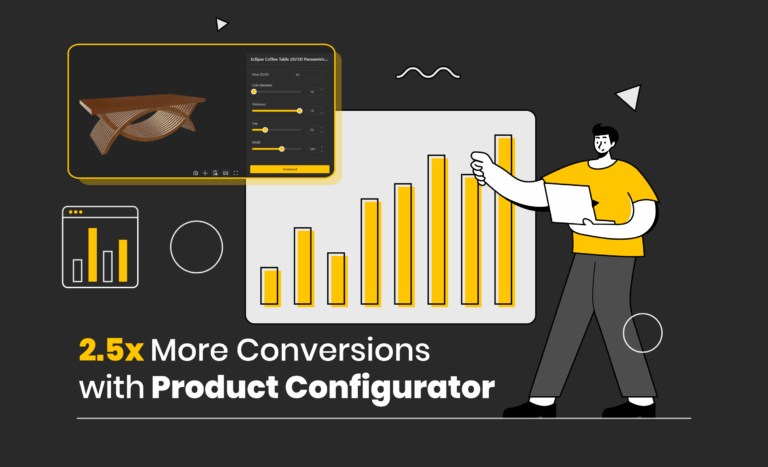

Platforms like BeeGraphy enable browser-based modeling with visual scripting and team collaboration, while Configurator.tech lets designers embed real-time 3D configurators into websites, turning static product pages into interactive experiences.

This shift isn’t just technical, it’s cultural. Parametric design aligns with the values of today’s creators: personalization, sustainability, and responsiveness. Shoes can be made to order, design variations take minutes, not weeks and products can evolve with user feedback.

You don’t need a lab or a big brand to innovate. Just the right mindset and the right tools. Start modeling using parametric controls. Make it interactive with product configurators. And the next Futurecraft might come from you.