Table of Contents

A Complete Workflow Using BeeGraphy

Design is rapidly shifting from static drawings to dynamic, rule-based digital systems. Parametric design platforms now allow creators to build products, installations, furniture systems, and architectural components that can adjust to infinite variations while remaining fabrication ready. One of the best things about this change is that you can now automate the Bill of Materials (BOM) directly from a parametric model.

Instead of calculating dimensions manually or rechecking measurements whenever a client requests changes, designers can now build a computational model that understands its own geometry. Once this logic is built in BeeGraphy, the system can generate real-time material quantities, fabrication data, and cost breakdowns for any variation of the design.

This blog post goes into more detail about the whole process, from making a logic-based model in BeeGraphy to turning it into a client-facing product configurator in Beegraphy that makes accurate BOMs and prices right away. If you work in furniture, interiors, architecture, or any form of mass customization, this workflow helps you cut down repetitive work and maintain complete precision.

1. Why Parametric Models Are Perfect for Automated BOM Generation

Static designs are often employed in traditional design workflows, and once client changes are made, they become irrelevant. Every time a change is made, designers have to update costing sheets, recalculate quantities, and update drawings. This overage, not to mention human error, slows down an iterative design to production process.

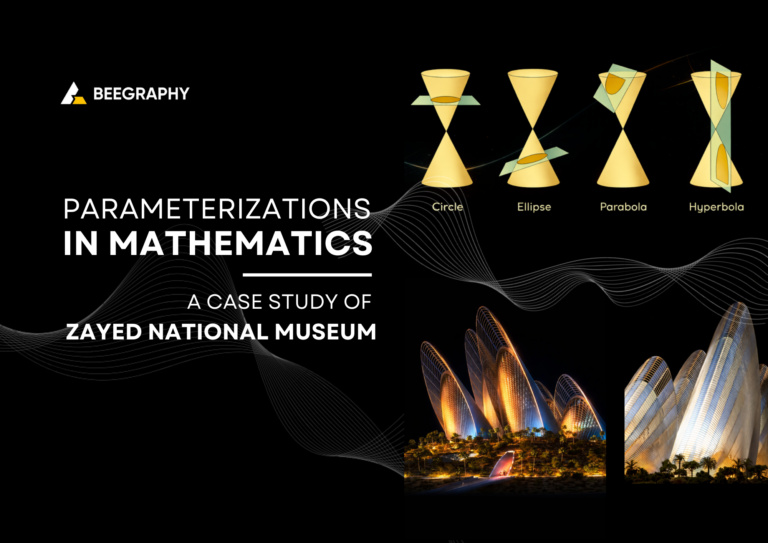

Parametric design fundamentally changes the method of thinking, switching from sketching geometry to defining logic, which completely eliminates this problem. Instead of modeling each part separately, you define the relationships, constraints, and logical rules that the geometry must comply with. The design becomes a living system, as opposed to a static model.

Because of this logic driven structure, parametric models are naturally equipped to calculate data such as:

- Component lengths

- Surface areas

- Material thicknesses

- Repetition counts

- Joint or connector positions

- Panel divisions

- Waste factors or tolerances

At BeeGraphy, every curve, surface, and solid has attributes that are measurable. Once you reveal those attributes inside the visual logic system, the BOM essentially becomes a byproduct of the model. You no longer have to create Excel sheets or manually count.

Any time the user changes a dimension, the rules will regenerate the geometry automatically, and any related data will update instantaneously. This creates a single source of truth for geometry and materials, which is critical for consistency in fabrication workflows.

2. Step by Step, How BeeGraphy Generates an Accurate BOM

BeeGraphy provides a visual node-based system where geometry and data workflows coexist. Here is how designers usually create an automated BOM inside BeeGraphy.

Step 1. Build the core parametric geometry

Start by defining the logic of the design. This may include base curves, profiles, frame structures, panel divisions, attractor systems, modular sequences, or any set of computational rules. For example, if you create a spiral staircase, you define relationships between riser height, tread depth, total height, and rotation. These values can be controlled through user-defined parameters.

Step 2. Define measurable attributes

Every geometric element can be analyzed through BeeGraphy nodes. You can extract:

- Length

- Area

- Volume

- Segment count

- Bounding box dimensions

- Edge lengths

- Centerline distances

These quantifiable properties form the foundation of the BOM. BeeGraphy treats geometry as data, which makes the extraction precise and parametric.

Step 3. Convert measurements into material requirements

Once you extract the geometry attributes, the next step is to convert them into material quantities. BeeGraphy allows you to add parameters for sheet size, wood density, extrusion length, material thickness, rod size, and more.

Examples:

- Total panel area divided by the area of an 8 by 4 sheet gives the required number of sheets.

- Total rod length divided by the available stock length gives the number of rods.

- Total surface area multiplied by coating efficiency gives paint or finish quantity.

This step transforms geometric data into fabrication logic. The model now understands what it needs to build itself in real life.

Step 4. Export the BOM as structured data

BeeGraphy can output JSON, CSV, or other structured data formats containing:

- Component names

- Dimensions

- Material type

- Part quantities

- Finish type

- Thickness or density

- Cost per unit if added

- Waste or tolerance factors

This export becomes the backbone that Beegraphy’s product configurator uses to visualize and calculate variations. The integration ensures that the data flows seamlessly between design logic and user interface.

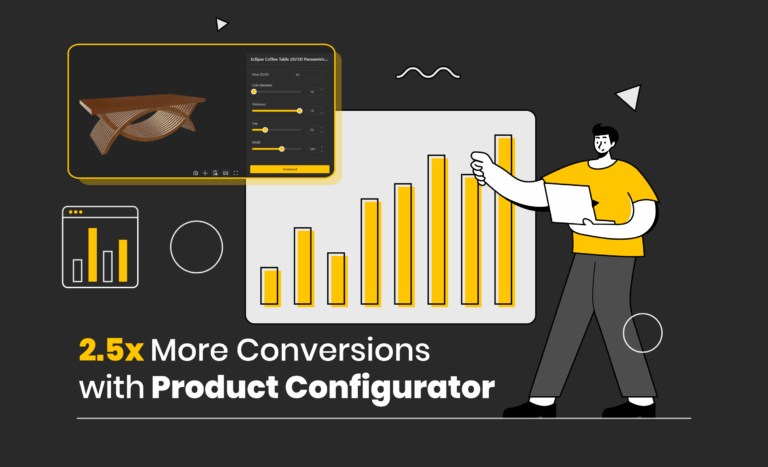

3. How Product Configurators Complete the Workflow

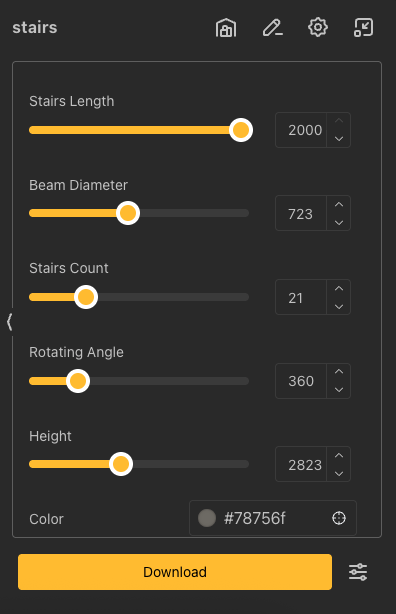

BeeGraphy creates the computational model. Configurators turn it into an interactive product that clients or consumers can modify without needing design software. This combination brings parametric design from the designer’s laptop to the world.

When you upload the BeeGraphy model to a product configurator, it becomes an online 3D product with custom controls such as:

- Sliders for height, width, depth

- Dropdowns for material selection

- Toggles for modules or add-ons

- Color pickers

- Checkboxes for optional features

- Presets for quick configurations

Every change the user makes triggers a live regeneration of the model. As the geometry changes, the connected BOM data recalculates automatically. This means the platform is not just visual; it is fully data driven.

This is incredibly useful for businesses offering custom furniture, modular interiors, small architecture products, or any design that requires mass customization. The user gets full freedom to explore variations while staying within safe constraints defined in BeeGraphy.

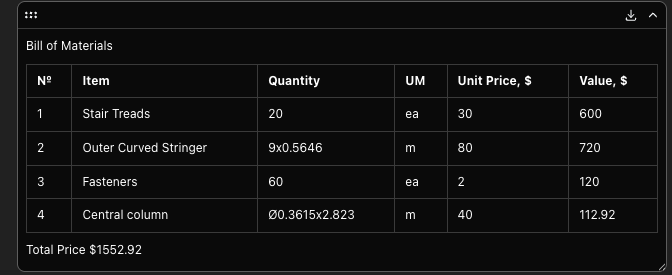

4. Real-Time BOM and Instant Costing

This combined workflow becomes powerful when real-time data and pricing enter the picture.

Live BOM updates

Product Configurators reads the BeeGraphy data and updates:

- Total material requirementss

- Component lengths and areas

- Quantity of panels and profiles

- Joinery counts

- Finish requirements

Automatic costing rules

You can add price rules for materials, finishes, modules, and fabrication steps. The configurator then shows:

- Total project cost

- Cost per material

- Labor or machine fees

- Add-on costs for optional modules

This helps businesses maintain complete transparency with customers.

Fabrication-ready downloads

Depending on the setup, users can export:

- CSV BOM files

- Order lists

- Cut lists

- DXF or CNC ready drawings

- Rendered views

- Technical documents

This creates a near-automated path from design to production. It eliminates repetitive tasks and ensures that every variation is accurate and ready for fabrication.

5. Real-World Example. A Parametric Furniture System

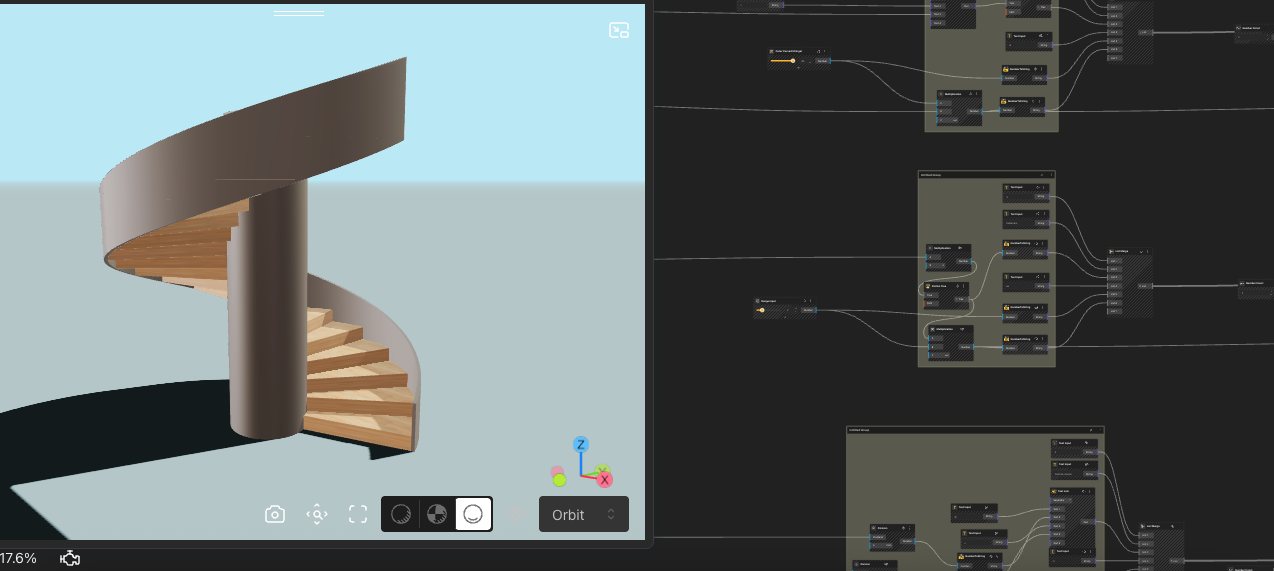

Imagine a modular spiral stairs that adjusts in height, width, number of steps, material type, and finish.

Inside BeeGraphy

The designer defines:

- Step height

- Number of vertical modules

- Panel thickness

- Bracket spacing

- Timber or material type

BeeGraphy calculates:

- Length of each vertical member

- Total panel area

- Timber volume

- Number of connectors

- Bracket count per module

All of this becomes structured BOM data.

Inside product configurators

A user can:

- Move sliders to adjust width or height

- Choose materials like oak, metal, or plastic

- Change colors and finishes

- Add or remove modules

Each change triggers:

- Updated panel quantities

- Updated rod or profile lengths

- Connector and joinery counts

- Updated material cost

- Updated total price

Once the user confirms, they receive a fabrication-ready BOM in their dashboard. This entire process happens without a single manual recalculation.

6. Why This Workflow Matters for the Future of Design

This workflow represents the direction the design industry is moving toward. Parametric logic creates reliability. Configurator create accessibility. Together, they form a system where design, data, and production are connected.

Key advantages include:

- Zero miscalculations

- No need to redraw or remodel

- Instant design variations

- Faster client approvals

- Accurate fabrication data

- Scalable mass customization

- Transparent pricing models

- Reduced workload on designers

Designers can build a logic once and use it for thousands of variations. Businesses can scale without scaling their design teams. Clients get complete control while staying within constraints that guarantee manufacturability.

This combination of computational design and online configurators is transforming industries. It makes design smarter, businesses faster, and fabrication more accurate.

Conclusion

BeeGraphy gives designers full computational control. Beegraphy’s Product Configurators give users an interface to explore variations. Together, they form a continuous pipeline in which geometry, materials, data, and production are perfectly synchronized.

You create the logic once. The system handles every variation forever. This is the future of design, a future where creativity, computation, and automation work together.

Learn more about the configurator here.

Check out the stair model here and the configurator here