Table of Contents

Introduction

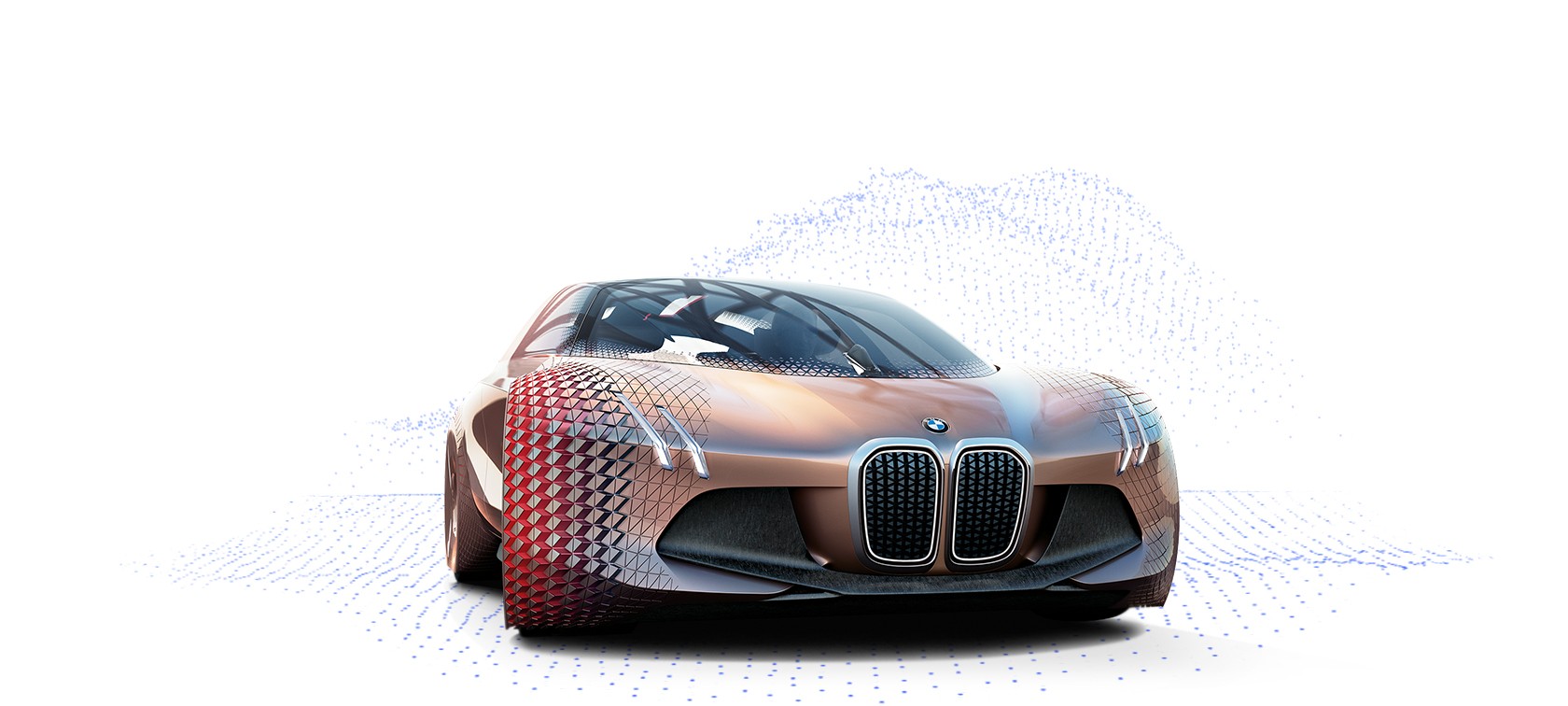

Almost a decade ago, BMW unveiled the Vision Next 100, a concept car that redefined the boundaries of automotive design. Developed to celebrate BMW’s centenary, this vehicle was not merely a futuristic prototype but a bold statement about the future of mobility. It combined aesthetics, technology, and sustainability in a single vision, demonstrating that cars can be dynamic, responsive, and tailored to the driver’s needs.

The Vision Next 100 embodies a significant shift from traditional workflows. In earlier eras, designing a car involved sketches, clay models, and manual iterations, often consuming months or even years to finalize a single concept. BMW took a different approach by incorporating advanced computational design methods, enabling engineers and designers to explore multiple variations simultaneously. This allowed for the creation of fluid, adaptive forms that could change in response to environmental conditions and user interaction. Even smaller, budget-friendly cars like the Maruti Dzire and Tata Nexon now apply similar principles on a smaller scale, optimizing body shapes, airflow, and structural layouts to improve efficiency and safety.

BMW Vision Next 100 concept overview

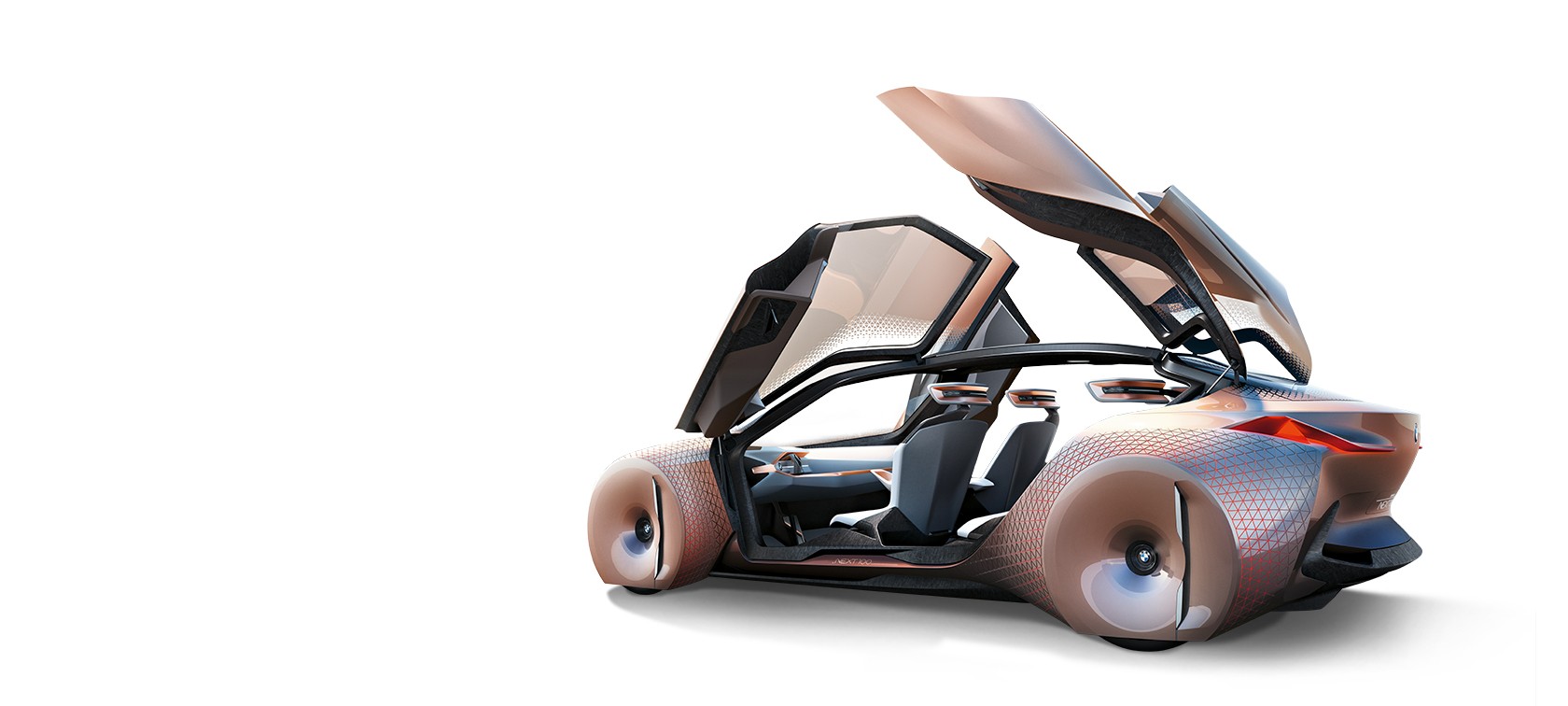

The car’s exterior is striking, with fluid lines and dynamic proportions carefully engineered to enhance performance and visual appeal. Seamless panel integration and smooth transitions between surfaces create a sleek, almost liquid appearance. Wheel arches expand or contract depending on speed, and body panels subtly shift to improve aerodynamics. These adjustments happen automatically, demonstrating the high level of thought and precision in the vehicle’s design.

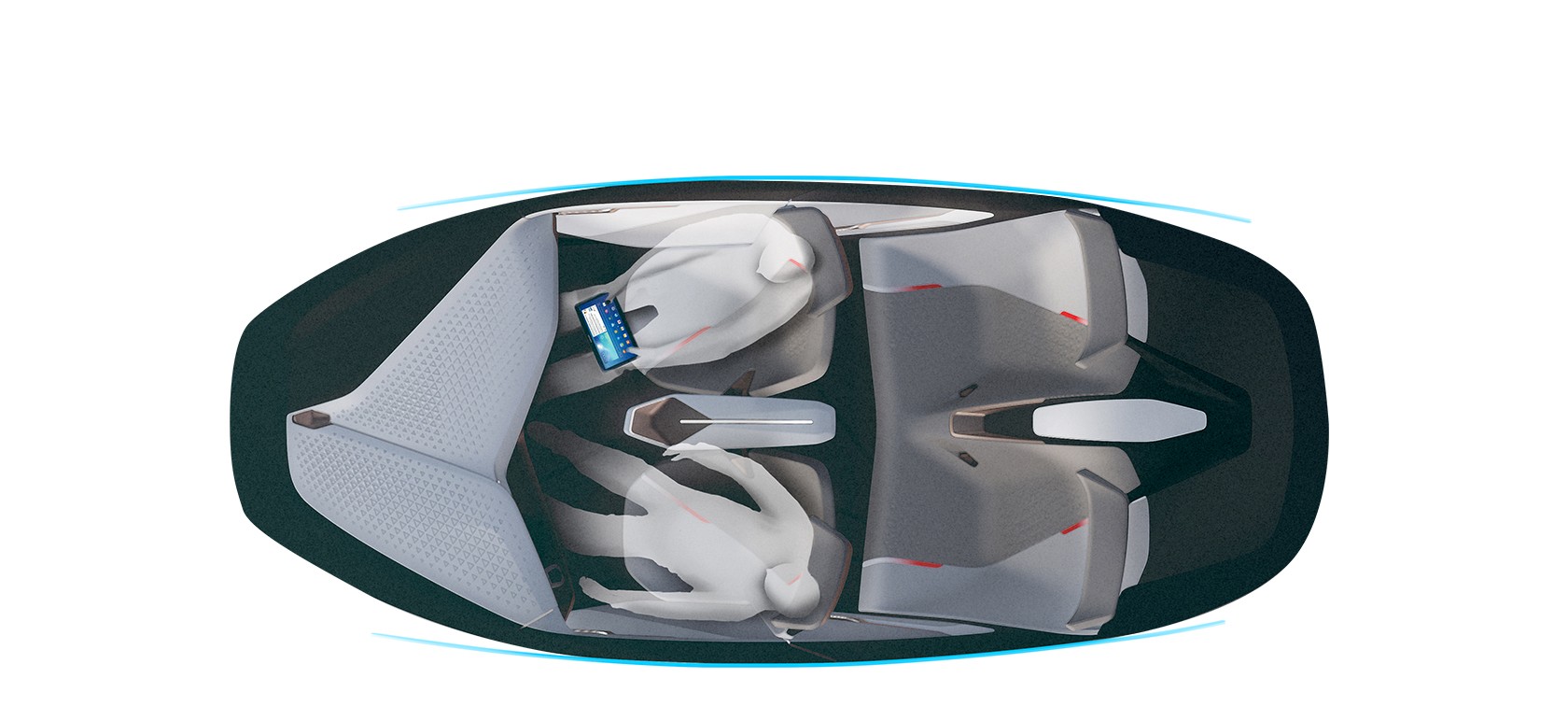

Inside, the Vision Next 100 introduces “The Companion,” an intelligent co-pilot that learns from the driver and adjusts the cabin environment accordingly. Seat positions, display layouts, and interactive surfaces change based on driver preferences, trip length, and driving mode. Materials are selected for comfort, durability, and sustainability, ensuring that luxury does not compromise environmental responsibility. By combining responsive interiors with advanced interfaces, BMW created a driving experience that is immersive, personalized, and forward-looking.

Autonomous driving is another defining feature. The Vision Next 100 can take over driving tasks entirely, allowing the driver to relax or focus on other activities. Advanced sensors, artificial intelligence, and predictive algorithms monitor traffic conditions and anticipate hazards, ensuring both safety and efficiency. While fully autonomous systems are still emerging in mainstream vehicles, this technology provides a glimpse of the possibilities for future mobility.

Sustainability is embedded throughout the vehicle. BMW uses recycled materials, renewable resources, and energy-efficient systems to reduce the environmental impact. These strategies are increasingly applied to mainstream vehicles, proving that eco-friendly design can coexist with performance, luxury, and affordability.

Case Study: BMW Vision Next 100

“If, as a designer, you are able to imagine something, there’s a good chance it could one day become reality,” said BMW’s design chief Adrian van Hooydonk. “So our objective with the BMW Vision Next 100 was to develop a future scenario that people would engage with.”

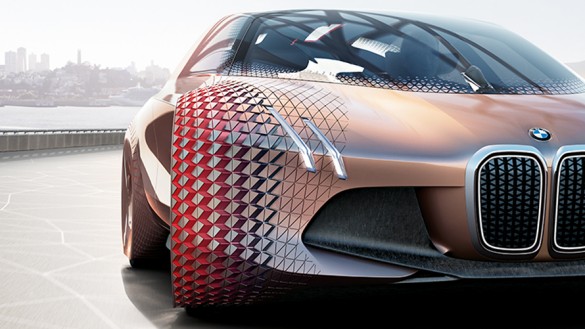

The concept vehicle features 800 moving triangles, which are set into the instrument panel and fitted to the side panels on the outside. These small, tessellated panels are not just decorative; they embody the car’s intelligence and adaptability. As the vehicle accelerates, turns, or changes modes, these triangular segments stretch, compress, and shift in a coordinated motion, creating a living skin that visually communicates the car’s behavior. When the wheels turn, for instance, the panels above them expand outward to accommodate the motion, revealing a red metallic underside that glows subtly beneath the copper-toned surface. This transformation is both aesthetic and functional it gives the sense of a machine that breathes and reacts, a seamless dialogue between motion and design.

Inside, this geometric narrative continues. The interior panels, dashboard, and seat surrounds repeat the triangular pattern language of the exterior, maintaining a visual and conceptual coherence. The dashboard itself becomes a dynamic surface, not a static array of screens, but a responsive interface. Hundreds of small, interlinked triangles extend and retract to signal information to the driver, such as upcoming turns or environmental alerts. Rather than relying on intrusive displays, the car communicates through motion and form. This represents a fundamental shift in interaction design: instead of overwhelming drivers with data, the Vision Next 100 makes the car’s body speak through subtle, intuitive cues.

Technically, the Alive Geometry panels are made from flexible materials connected to actuators beneath the surface. Each movement is synchronized with real-time driving data: acceleration, steering angle, speed, and environmental feedback. This micro-mechanical system allows the car to adapt aerodynamically, narrowing air passages during high-speed travel to reduce drag or widening them in tight turns for stability and grip. The precision of this motion gives the impression of a responsive organism rather than a mechanical shell.

For computational designers, this approach mirrors the logic of parametric modeling platforms like BeeGraphy or Grasshopper, where changing one variable cascades through the system, updating the entire design coherently. The Vision Next 100, therefore, is not just a concept car but a visual metaphor for computational design itself: iterative, adaptive, and deeply integrated.

Ultimately, what makes the BMW Vision Next 100 so captivating is how it blurs the line between art and engineering. The 800 triangles are not ornamental but symbolic of a new design paradigm, one that treats the vehicle as a living, responsive entity. Each motion of the panels, each subtle glow from the red underlayer, and each ripple of the copper skin tells a story of evolution from static machines to emotionally intelligent companions. It’s a vision of the future where technology breathes, design listens, and motion itself becomes an act of communication

Tutorial: Modeling BMW Vision Next 100 Patterns in BeeGraphy

For aspiring designers and students, the Vision Next 100 provides an excellent foundation for exploring computational modeling in BeeGraphy. Its flowing surfaces, repeating elements, and modular components can be recreated as interactive nodes, demonstrating the principles of geometry, connectivity, and adaptability.

Lets make the triangular pattern of the legendary car in Beegraphy’s editor.

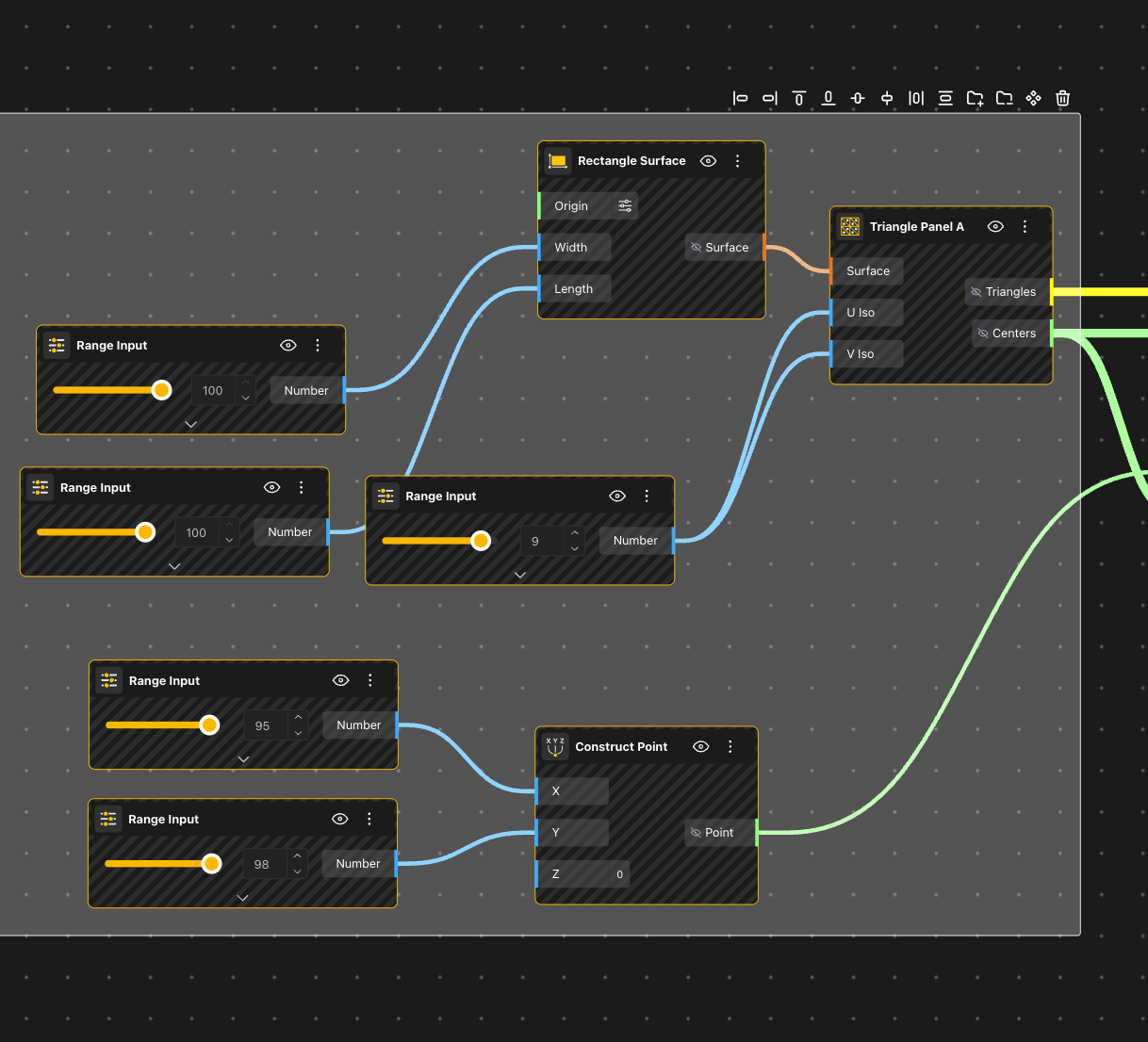

Step 1: Base Geometry Setup

- Start by creating a Rectangle Surface node.

- Connect two Range Input nodes to the Width and Length inputs of the rectangle to control its size.

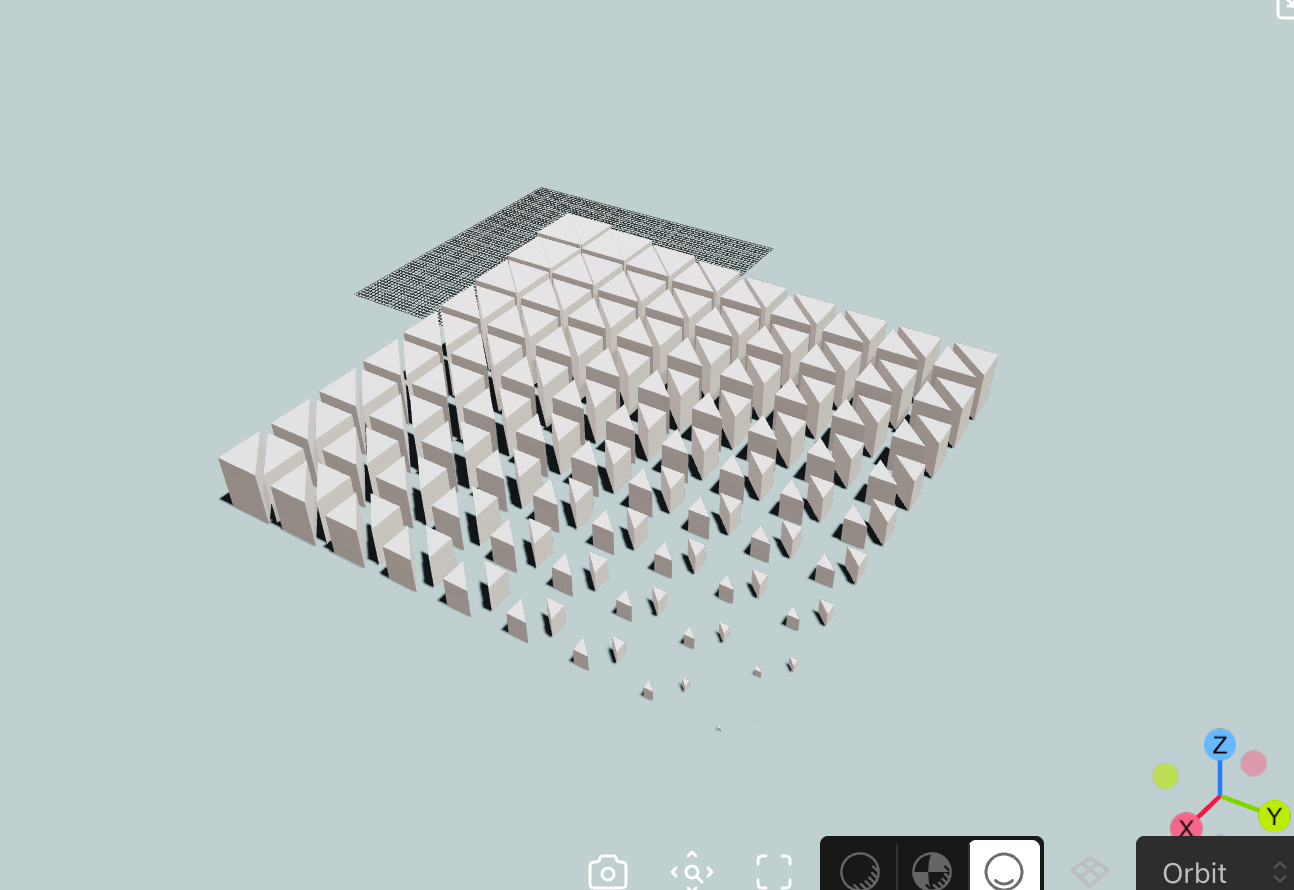

- Use a Triangular Panel node and connect the rectangle’s surface output to it. This divides your surface into triangular panels that will be affected by the attractor logic later.

Step 2: Finding the Distance Between Each Triangle and the Attractor Point

- Create an Attractor Point using a Construct Point node, with two Range Input nodes controlling its X and Y coordinates.

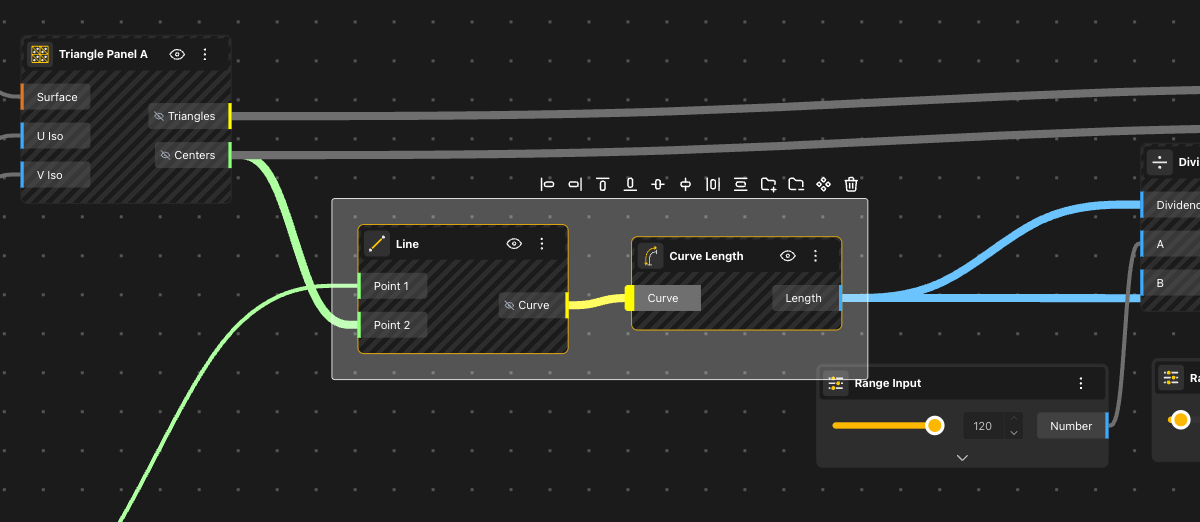

- Connect the center points of the triangles from the Triangular Panel node to a Line node along with the attractor point. This creates connecting lines from each triangle to the attractor.

- Use a Curve Length node to measure the distance between the attractor point and each triangle’s center.

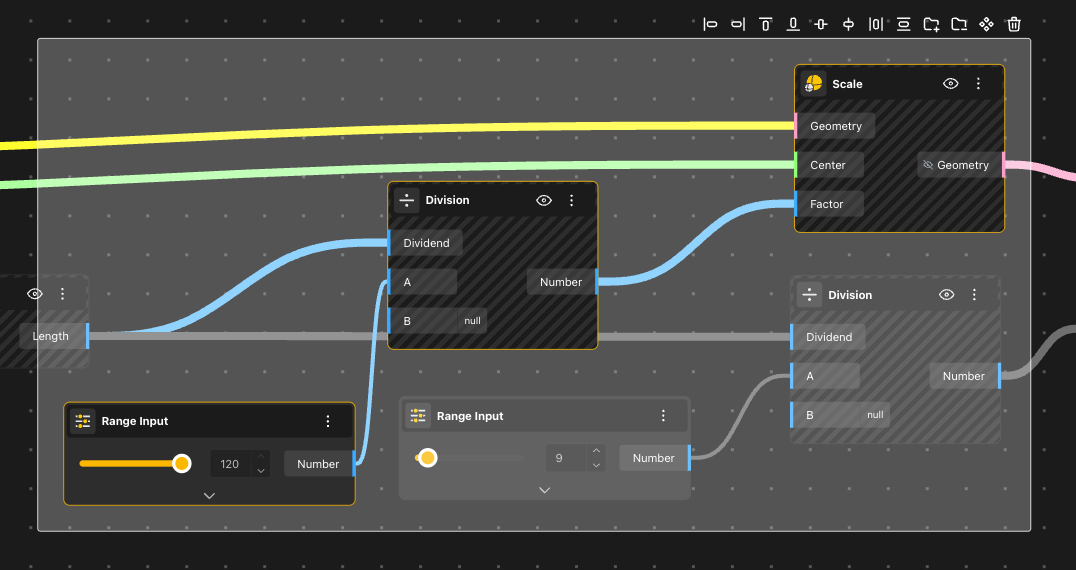

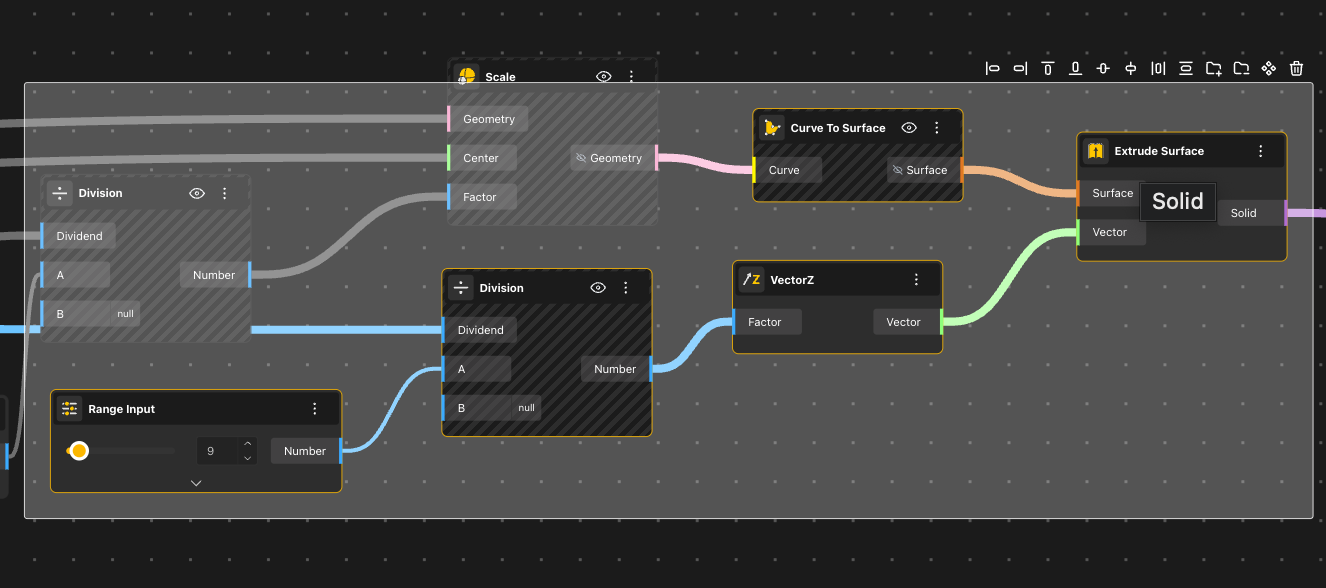

Step 3: Scale According to Attractor Distance

- Feed the curve lengths into a Division node to normalize the distance values (you can divide by a constant value to control falloff).

- Connect the result to a Scale node as the scale factor.

- Input the triangular geometry into the Scale node so that each triangle scales based on its distance from the attractor point.

- Closer triangles appear larger or smaller depending on how you invert the value.

- Farther triangles scale differently, creating the attractor effect.

Step 4: Extrusion

- Convert the scaled triangles into surfaces using a Curve to Surface node.

- Create a Vector Z node to define the extrusion direction and magnitude.

- Connect both to an Extrude Surface node.

- Finally, use an Apply Material node to assign a color or material to the geometry for visualization.

Conclusion

The BMW Vision Next 100 is more than a concept car; it is a roadmap for future mobility. It demonstrates how innovation, user-centered design, and intelligent engineering can merge to create dynamic, responsive, and visually compelling vehicles. Lessons from the Vision Next 100 extend to both luxury and budget vehicles, inspiring new approaches to efficiency, safety, and adaptability.

For learners and computational designers, studying this vehicle provides a rich understanding of how advanced design strategies can be applied in software environments like BeeGraphy. By exploring its surfaces, patterns, and adaptable components, designers can develop practical skills, experiment with geometry, and gain a deep appreciation for the interplay between aesthetics and function in modern automotive design.

Ultimately, the Vision Next 100 represents a milestone in automotive innovation, bridging the gap between imagination and real-world application. It inspires designers to push the boundaries of creativity while grounding their work in technical feasibility, preparing them to contribute meaningfully to the next generation of vehicles.