Table of Contents

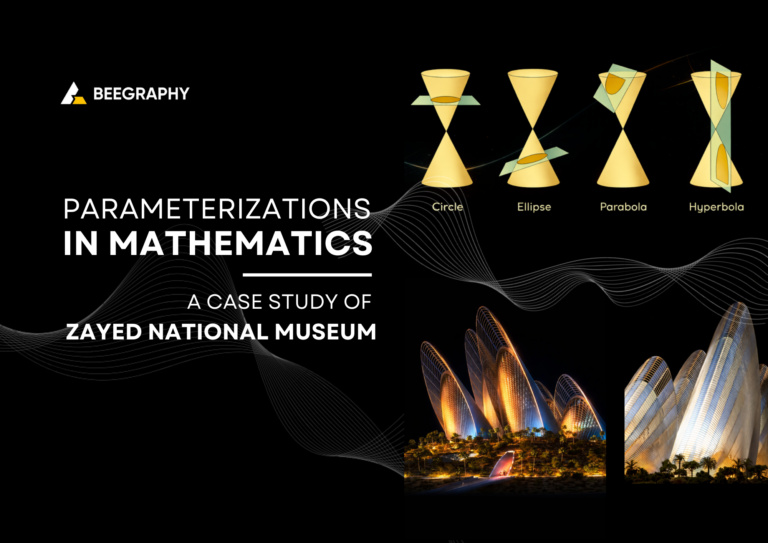

As part of the ongoing Beegraphy Design Awards – A Computational Design Challenge Series, we are excited to delve into the transformative intersection of parametric lighting design and digital fabrication, particularly within the realm of lighting design. The Beegraphy Design Awards celebrate innovation and creativity in computational design, providing a platform for designers to push the boundaries of what’s possible. This blog explores how the integration of parametric design with advanced digital fabrication techniques is revolutionizing the way we approach lighting solutions, offering unprecedented possibilities for customization, efficiency, and artistic expression.

In this article, we’ll journey through the principles of parametric design, examine its synergy with digital fabrication, and showcase inspiring case studies of lighting fixtures that exemplify this cutting-edge approach. Whether you’re a seasoned professional or an emerging designer, this exploration aims to inspire your next venture into the world of computational design.

Understanding Parametric Design

Parametric design represents a paradigm shift in how we conceptualize and create design solutions. Unlike traditional design methods, which rely on static, predefined shapes and forms, parametric design is driven by algorithms and parameters that allow for dynamic, flexible, and responsive forms.

At its core, parametric design is about defining a set of rules or parameters that govern the relationships between different elements of a design. These parameters can include anything from spatial dimensions, material properties, and environmental conditions, to user interactions and aesthetic preferences. By adjusting these parameters, designers can generate an infinite variety of forms and solutions, all adhering to the underlying logic of the design.

Software tools like Grasshopper, Rhino, and Autodesk Maya have become essential in the parametric design process, enabling designers to create complex geometries that would be nearly impossible to achieve manually. These tools allow for the real-time manipulation of design parameters, providing instant visual feedback and the ability to explore a wide range of design possibilities. Beegraphy is an emerging computational design tool that enables real-time collaboration on cloud for the users.

In the context of lighting design, parametric design opens up new possibilities for customization and innovation. Designers can create lighting fixtures that are not only aesthetically striking but also optimized for specific functional requirements, such as light distribution, energy efficiency, and user interaction. This level of customization is particularly valuable in architectural projects where lighting plays a critical role in shaping the ambiance and functionality of a space.

The Intersection of Parametric Design and Digital Fabrication

The convergence of parametric design and digital fabrication is reshaping the landscape of lighting design, enabling the creation of complex and customized fixtures with a level of precision and efficiency that was previously unimaginable.

Digital fabrication refers to the use of computer-controlled processes to manufacture physical objects directly from digital models. This includes technologies such as 3D printing, CNC milling, and laser cutting, all of which have become indispensable tools in the production of parametric designs. These techniques allow for the direct translation of digital models into physical forms, bypassing many of the limitations associated with traditional manufacturing methods.

One of the key advantages of digital fabrication in the context of parametric design is the ability to produce highly intricate and complex geometries. Traditional manufacturing processes often struggle with the complexities inherent in parametric designs, which can involve organic shapes, fine details, and interlocking components. Digital fabrication, however, thrives on these complexities. For example, 3D printing can create structures with intricate internal cavities, complex curves, and varying material densities—all within a single, continuous process.

A Parametric lighting fixture made using Laser cut parts and assembled. Source: Etsy

Moreover, digital fabrication enables mass customization. Since each fixture can be produced directly from its digital model without the need for costly molds or tooling, designers can create unique, bespoke lighting solutions tailored to specific client needs or environmental conditions. This flexibility is particularly valuable in architectural lighting, where each space may require a different lighting approach based on factors like room size, ceiling height, and natural light availability.

The synergy between parametric design and digital fabrication also facilitates rapid prototyping and iterative design. Designers can quickly produce physical prototypes to test and refine their ideas, making adjustments to the digital model as needed before final production. This iterative process not only improves the final product but also reduces the time and cost associated with bringing a new design to market.

In practice, this means that lighting designers can experiment with forms and materials in ways that were previously constrained by the limits of traditional fabrication techniques. Whether it’s a sculptural chandelier with flowing organic forms or a minimalist pendant light optimized for energy efficiency, the possibilities are nearly endless.

Case Studies: Parametric Lighting Fixtures

To illustrate the transformative impact of parametric design and digital fabrication on lighting fixtures, let’s explore some notable case studies that showcase the potential of these technologies in creating innovative and functional lighting solutions.

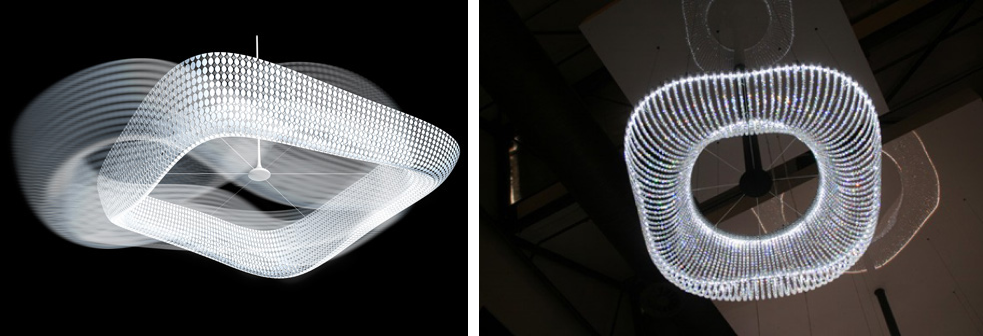

1. The “Morpheus” Chandelier

Designer: Yves Behar

Manufacturer: Swarovski

The “Morpheus” chandelier is a stunning example of how parametric design can be used to create a visually striking and highly functional lighting fixture. Designed using parametric modeling software, this chandelier features a series of interconnected, organic forms that change shape based on the ambient light conditions in the room.

Swarovski Morpheus Chandelier. Source: Yanko Design

Parametric Design: The chandelier’s design parameters include light intensity, distribution, and the interaction between light and shadow. These parameters are adjusted dynamically to adapt to different times of day and user preferences.

Digital Fabrication: Fabricated using a combination of 3D printing and CNC milling, the chandelier’s complex geometries were produced with high precision. The use of lightweight materials and advanced fabrication techniques allowed for the realization of the intricate, fluid forms.

The “Morpheus” chandelier not only serves as a functional light source but also as a sculptural art piece, adding a dynamic element to the space it illuminates.

2. The “Flux” Pendant Light

Design Firm: Haberdashery Ltd

Manufacture year: 2021

The “Flux” pendant light is a minimalist design that emphasizes clean lines and functional efficiency. The design leverages parametric modeling to optimize light distribution and energy consumption, resulting in a fixture that is both aesthetically pleasing and environmentally conscious.

Parametric Design: Key parameters include the angle and orientation of light emission, which are adjusted based on the intended use of the space. The design also incorporates considerations for glare reduction and visual comfort.

Digital Fabrication: Produced using laser cutting and CNC technology, the pendant light features precision-engineered components that fit together seamlessly. The use of sustainable materials further enhances the environmental benefits of the design.

The “Flux” pendant light demonstrates how parametric design can enhance both the functionality and sustainability of lighting solutions, making it ideal for modern, eco-friendly spaces.

3. The “Aurora” Interactive Lighting Installation

Design Firm: Cinimod Studio

Location: London, UK

The “Aurora” lighting installation is an interactive, parametric design that responds to user input and environmental changes. The installation creates a dynamic lighting experience that evolves throughout the day, engaging users in a multisensory interaction.

Parametric Design: The design incorporates parameters for user interaction, such as motion sensors and ambient light levels. The lighting patterns and colors change in response to these inputs, creating a personalized experience.

Digital Fabrication: Utilizing advanced 3D printing techniques, the installation’s modular components were produced with high precision. The integration of interactive elements required careful calibration and testing to ensure smooth operation.

The “Aurora” installation exemplifies how parametric design can be combined with interactive technology to create immersive and engaging lighting experiences.

Impact of Digital Fabrication on Parametric Lighting Design

The advent of digital fabrication technologies has had a profound impact on the field of parametric lighting design, enabling a range of new possibilities and redefining the boundaries of what is achievable in lighting fixtures. This section explores the key ways in which digital fabrication has transformed parametric lighting design and the implications for the future.

1. Enhanced Precision and Complexity

Digital fabrication techniques such as 3D printing, CNC milling, and laser cutting allow for unparalleled precision in the creation of parametric designs. Complex geometries and intricate details that were once difficult or impossible to achieve with traditional methods can now be realized with remarkable accuracy. This level of precision ensures that parametric lighting fixtures not only meet aesthetic expectations but also perform optimally in their intended environment.

- Complex Geometries: Designs with complex curves, interlocking parts, and fine details can be produced directly from digital models, enabling the creation of highly intricate and unique lighting fixtures.

- Material Optimization: Advanced fabrication techniques allow for the use of multiple materials and varying densities within a single fixture, optimizing both performance and aesthetics.

Computational design enables designers to fabricate intricate details using 3D Printing, CNC and laser cutting. Source: Etsy

2. Rapid Prototyping and Iterative Design

Digital fabrication enables rapid prototyping, allowing designers to quickly produce and test physical models of their parametric designs. This iterative process facilitates experimentation and refinement, leading to more effective and innovative lighting solutions. Designers can make adjustments to the digital model and re-fabricate prototypes as needed, streamlining the development process and improving the final product.

- Faster Development: Prototypes can be produced in a fraction of the time compared to traditional methods, accelerating the design process.

- Design Flexibility: Designers can experiment with different parameters and configurations to achieve the best possible result, without the constraints of manual fabrication.

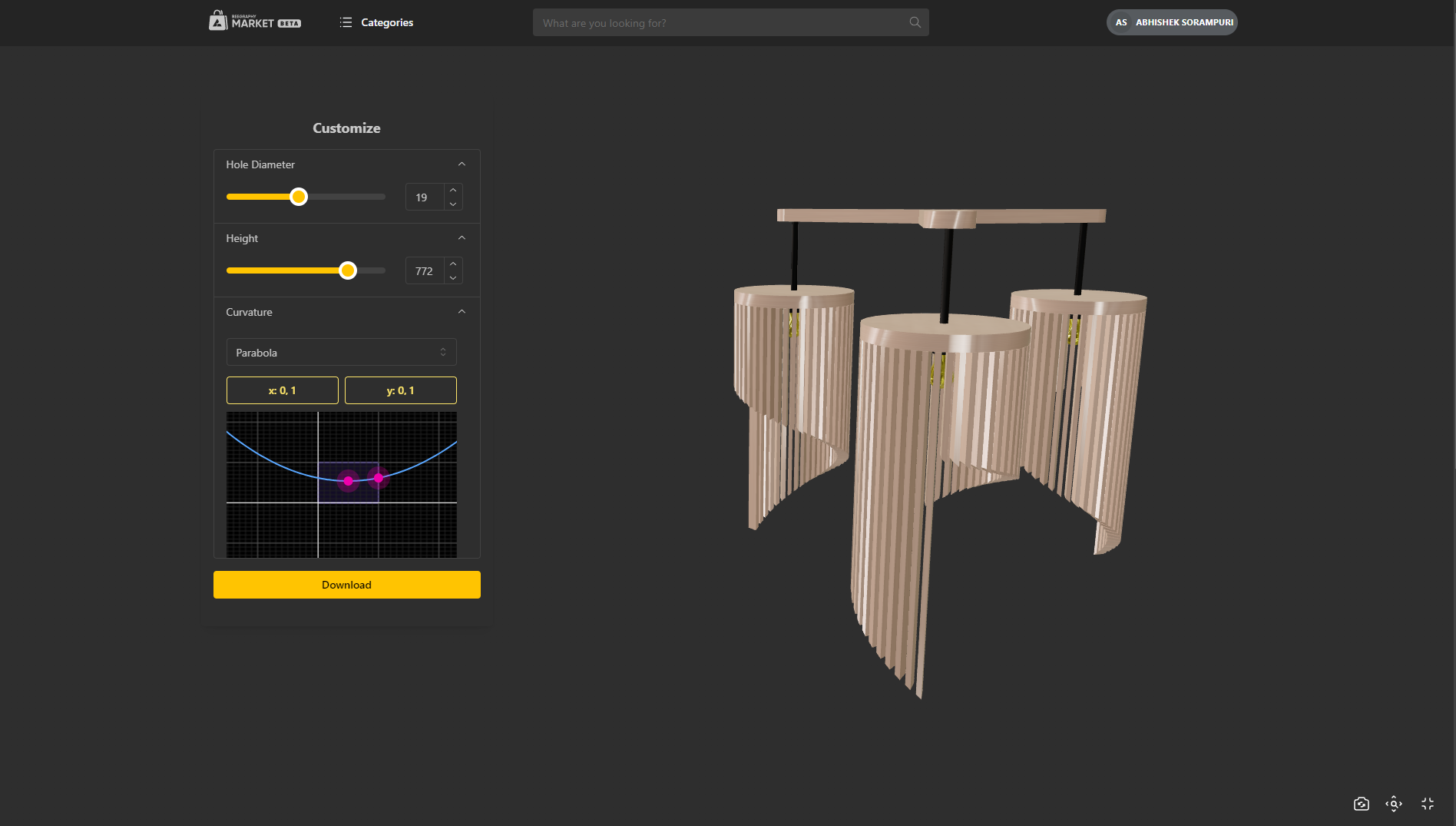

3. Mass Customization and Personalization

Digital fabrication allows for mass customization, where each lighting fixture can be tailored to specific client needs or project requirements. This capability is particularly valuable in architectural lighting, where fixtures need to adapt to various spatial and aesthetic conditions. By leveraging digital fabrication, designers can offer bespoke solutions without the high costs associated with traditional custom manufacturing.

- Tailored Solutions: Fixtures can be customized to fit specific dimensions, lighting requirements, and design preferences, providing a unique solution for each project.

- Cost Efficiency: Digital fabrication reduces the need for expensive molds and tooling, making customized solutions more accessible.

4. Sustainability and Material Efficiency

The use of digital fabrication in parametric lighting design contributes to sustainability by optimizing material usage and reducing waste. Techniques like 3D printing allow for additive manufacturing, where material is only used where needed, minimizing waste and energy consumption. Additionally, designers can choose sustainable materials and incorporate eco-friendly practices into the production process.

- Material Savings: Additive manufacturing techniques build objects layer by layer, using only the material necessary for the final product.

- Eco-Friendly Materials: Designers can select materials with lower environmental impact, such as recycled or biodegradable options.

Parametric Lighting fixture designed using recycled pine wood Panels.

5. Future Implications and Innovations

Looking ahead, the continued evolution of digital fabrication technologies promises even greater advancements in parametric lighting design. Emerging technologies such as AI-driven design, robotic fabrication, and advanced material science are set to further expand the possibilities. These innovations will likely lead to more sophisticated, interactive, and sustainable lighting solutions.

- AI-Driven Design: AI and machine learning can optimize design parameters and predict performance outcomes, enhancing the efficiency of the design process.

- Robotic Fabrication: Robotics can handle more complex and precise fabrication tasks, pushing the boundaries of what can be achieved with digital fabrication.

- Advanced Materials: New materials with unique properties, such as self-healing or energy-harvesting materials, will enable even more innovative lighting designs.

- Integration with IoT: IoT and smart technologies will enable lighting fixtures to adapt in real-time based on occupancy, time of day, and user preferences, enhancing both functionality and energy efficiency.

- Biophilic Design : Biophilic design will inspire lighting fixtures that mimic natural patterns and integrate with environmental conditions, improving occupants’ well-being and harmonizing with their surroundings.

- Collaborative Design Platforms and Digital Twins: Collaborative platforms like Beegraphy and digital twins will allow for virtual simulation, testing, and real-time collaboration, leading to more accurate and efficient development of lighting designs.

Final Thoughts

The convergence of parametric design and digital fabrication is set to redefine the future of lighting design, driven by advancements in AI, robotics, materials science, and smart technologies. As these trends continue to evolve, they will enable more innovative, efficient, and sustainable lighting solutions, paving the way for a new era in design and production.

We encourage all designers and innovators to embrace these emerging technologies and contribute to the future of lighting design. If you’re passionate about exploring the possibilities of parametric design and digital fabrication, consider participating in the Beegraphy Design Awards Lighting Fixtures category. This is an excellent opportunity to showcase your designs, take part in workshops, gain recognition, and be part of a vibrant community pushing the boundaries of lighting design.

Submit your design through Beegraphy and join us in shaping the future of lighting. For more information and to enter the competition, visit Beegraphy Design Awards Lighting Fixtures.

Together, let’s illuminate the future with creativity and innovation!