Table of Contents

Economic transformation, called industrialization, has changed the course of history. Starting in the 18th and 19th centuries in Europe and North America and expanding all over the world, the movement came to shift things with the power of industry.

Smart and connected technologies are transforming humankind and the global economy.

You are definitely familiar with the term “Industrial Revolution.” It’s when the industry became dominant in society and economics. The First Industrial Revolution started with agricultural communities becoming more industrialized and urban due to inventions of the steam engine, transcontinental railroads, the cotton gin, and electricity.

The process of creating things changed permanently as the opportunity for mass production appeared. Then, manufacturing was mainly revolutionized due to inventions. Today, various factors decide the future of the industry.

According to Deloitte, trends that are going to change manufacturing this decade and beyond are economic patterns, trade dynamism, digitization, talent/future of work, and electrification.

Advancements in the modern world brought us to the Fourth Industrial Revolution.

Let’s dive deeper and see what it is all about and how it will disrupt the world.

What is Industry 4.0, and how did it begin?

The idea of Industry 4 is that modern global value chains enable smart factories, creating a world, where virtual and physical systems of manufacturing cooperate in a flexible way.

Walking through history, we’ll see the tremendous growth our world has made due to technological development. After the First Industrial Revolution, more innovations came to the world, leading to new revolutions.

The Second Industrial Revolution, also called “The Technological Revolution” started about a century later after the first one, at the end of the 19th century. It was powered by massive technological inventions in industries that helped the creation of a new source of energy – electricity, gas, and oil. The creation of electricity powered even greater production. This era is notable for the start of mass production in manufacturing and customer goods. Among the revolutionary inventions were the telegraph, the telephone, the automobile, and the plane.

The Third Industrial Revolution is otherwise known as the “Digital Revolution,” as it is characterized by the invention of the internet, automation, and digitization. Industry 3.0 started in the late 1900s and saw the growth of electronics. Computers and new technologies enabled globalization, low-cost economies, and new business models worldwide.

The Fourth Industrial Revolution is also known as Industry 4.0, 4IR, advanced or smart manufacturing. Discussions around the new industrial revolution started in 2011 at the Hannover Fair, a trade fair dedicated to industrial technologies in Germany. The idea is that modern global value chains enable smart factories, creating a world, where virtual and physical systems of manufacturing cooperate in a flexible way. In a book, called “The Fourth Industrial Revolution“, published in 2016, the founder of the World Economic Forum Klaus Schwab says:

“We are at the beginning of a revolution that is fundamentally changing the way we live, work, and relate to one another. In its scale, scope and complexity, what I consider to be the fourth industrial revolution is unlike anything humankind has experienced before. “

He mentions that there are unlimited possibilities as technology enables billions of people to be connected by mobile devices, and access exceptional processing power, storage capabilities, and knowledge.

With Industry 4.0, previously separate industrial structures, technologies, media, and solutions work together to add efficiency and value to the production process.

Emerging technology breakthroughs such as artificial intelligence (AI), robotics, the internet of things (IoT), 3D printing, nanotechnology, biotechnology, materials science, energy storage, cloud computing, and others, cover a wide range of fields. With Industry 4.0 digital connectivity reached another level, which provides the opportunity to change essentially the way industry responds to the needs of society.

What are the key benefits of Industry 4.0?

Exploring the possibilities, it becomes apparent that emerging trends in this new era of production and consumption are significantly different from what could be achieved before. The question arises: how the new level of digital connectivity and advanced technologies are reshaping the industry, and what benefits do they bring? Let’s take a look at some of the main advantages of Industry 4.0:

Operational efficiency

With Industry 4.0, previously separate industrial structures, technologies, media, and solutions work together to add efficiency and value to the production process. Integrated network solutions and automation now allow self-organizing and flexible solutions in real-time, speeding up the product lifecycle and improving the use of resources. Now, an advanced innovative system that integrates software and hardware solutions, can be responsible for all processes, connecting Computer-Aided Design (CAD), planning, management, data generation, material flow, and relevant production process. Technology nowadays offers quicker workflow, greater precision, higher reliability, and fast evaluation.

A study on smart factories by Deloitte found that after investing in smart factory initiatives, companies saw a 10-12% increase in areas like manufacturing output, factory utilization, and labor productivity.

Enhanced customer experience

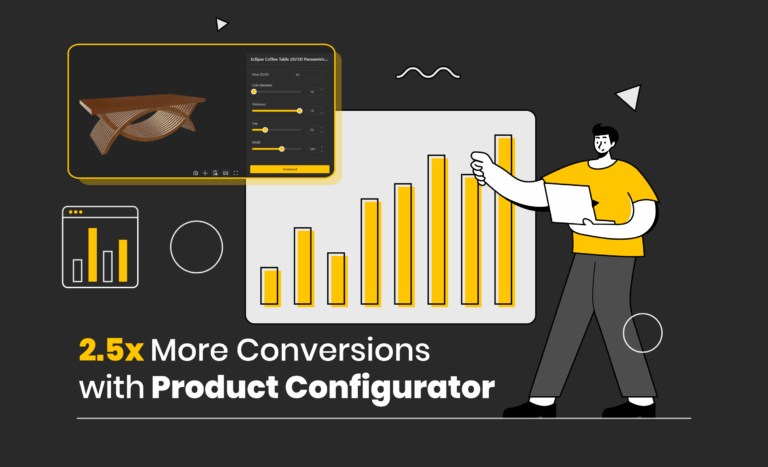

One of the main factors that drive the transformation in manufacturing is the goal to meet growing customer requirements. To achieve this, individuals and companies aim to fulfill dynamic and individualized customer requests quickly. At the same time, technologies increase user engagement, helping them have a clearer understanding of the product before making a purchase.

Among the innovations that make the new level of customer experience are the Internet of Things (IoT), Artificial Intelligence, additive manufacturing, 3D printing, robotics, high-performance computing, Augmented Reality, and others. According to research, the Customer Engagement Solutions Market Size is expected to increase by $7.69 bln from 2021 to 2026 with a Compound Annual Growth Rate of 8.42%.

New forms of collaboration

New tools and platforms power effective collaborations between companies to join efforts and develop innovative solutions. At the same time, human-machine relations are taking new forms with the emergence of next-generation robots. You can see more and more exciting startups, partnerships, and projects that are driving the transformation of the world. One of them is the collaboration between the World Economic Forum, Accenture, and Microsoft. The companies came together to build an environment for partnerships in the metaverse. Called “Global Collaboration Village,” the platform aims to provide large spaces where different organizations and companies can co-create and work on solutions to face global challenges.

Smart tech and customizable product manufacturing are the core of the fourth Industrial Revolution.

Sustainable manufacturing

Due to Industry 4.0, it is possible to track materials and flows and analyze them to achieve significant gains in resource use and efficiency. Not only do innovations help decrease manufacturing impact on the environment, but they can be used to recover nature through sustainable production and consumption.

One of the revolutionary innovations is the use of so-called self-driving cars. Although the idea has been around for centuries, it seems to be close to its implementation now. A study found that these vehicles may save 90% of fuel if used the right way. By controlling speed, braking, and driving style they can burn less gas and reduce air pollution. Automated driving systems sense the environment and respond accordingly. Technology replaces driver’s assistance with automated features.

Employment growth in cognitive and creative jobs

Modern technologies will drastically change the nature of work across all industries. There are concerns if automated systems can replace some workers, forcing them to become unemployed or leverage their skills somewhere else.

WEF founder Klaus Schwab says: “The destruction effect is accompanied by a capitalization effect in which the demand for new goods and services increases and leads to the creation of new occupations, businesses, and even industries.”

The change will enable the emergence of new types of jobs that are extremely flexible and on-demand. According to the Oxford Martin Programme on Technology and Employment, there will be growing employment in high-income cognitive and creative jobs.

What are the applications of industry 4 in different fields?

Smart and connected technologies are transforming humankind and the global economy. Looking around, we can already see innovations disrupting every field, and offering new solutions. According to a study by the European Patent Office (EPO), in the last decade, the pace of Industry 4.0 technologies increased essentially. These digital technologies account for 10% of all innovation, and annual growth rates for patent applications (20%) are running at five times the baseline growth rate for all technologies.

Among the areas that have benefited greatly from the Industry 4.0 technologies are:

Manufacturing/production

Germany Trade and Invest notes: “Industrial production machinery no longer simply “process” the product, but the product communicates with the machinery to tell it exactly what to do.

Advanced technologies allow building products that are smarter, more connected, and more responsive. At the same time, 3D printing, Computer-Aided Design, custom manufacturing, and new materials are making it possible to produce products more quickly, carry out real-time readjustments, and modifications, and achieve greater customization.

Marketing and sales

According to Noah Elkin, Chief Sales Officer at Gartner: “Smarter use of data will help marketers respond faster – and better – to business challenges.”

Digitization allows the use of information on customer base, and technology infrastructure to get insights into user needs and behaviors and build marketing and sales decisions based on the received data.

Due to Industry 4.0 technologies, data from different sources such as big data and cloud computing can be combined and shared. Digitization allows the use of information on customer base, and technology infrastructure to get insights into user needs and behaviors and build marketing and sales decisions based on the received data. Leveraging analytics helps provide customers with more advanced services, enhancing quality and speed.

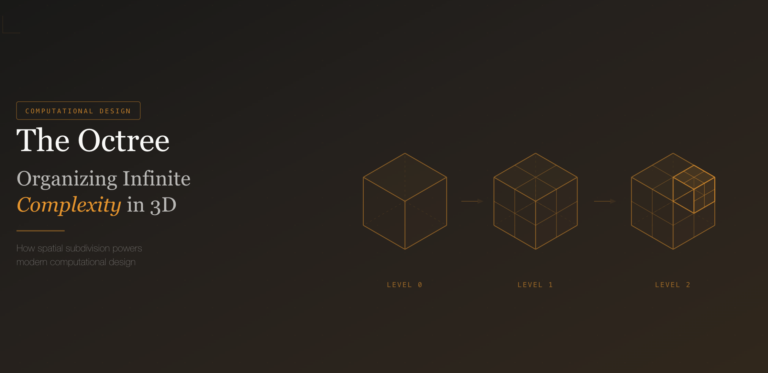

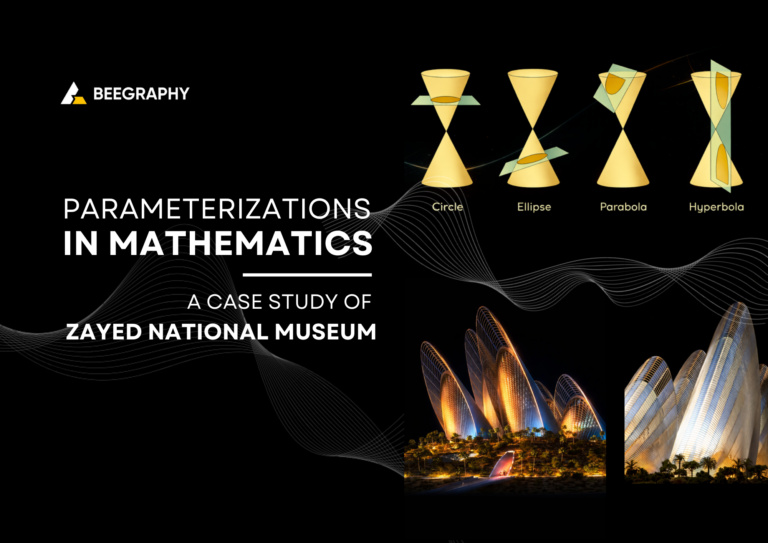

Design and architecture

Now, designers and architects are able to use computational design, additive manufacturing, material engineering, and synthetic biology to make consumer products, buildings, and various structures that are highly adaptable.

Due to the access to high-resolution tools, it is possible to plan and prototype products with enhanced precision and higher reliability to bring previously impossible ideas to life. A combination of technology, nature, and creativity can be seen in different projects. One of them is “Aguahoja,” created by designer Neri Oxman and the Massachusetts Institute of Technology (MIT). Aguahoja is an architectural structure made from organic materials like fallen leaves, apple skins, and shrimp shells. The piece was 3D printed by robots. It was shaped and designed to be transformed by water.

Transportation

Industry 4.0 technologies allow virtual and physical worlds to work closely together, which results in more decentralized manufacturing processes. Large businesses and individual entrepreneurs can work in a self-directed way and in real-time due to networking, the internet, and interconnected software. Innovative technologies manage processes like storage, production, data exchange, and monitoring in the blink of an eye, transforming the supply chain.

A report by Deloitte says:

“In the era of Industry 4.0 where markets have become more competitive and customer requirements are more individualized, companies are continuously looking for alternatives to optimize their warehouse processes, increase warehouse productivity, provide better service levels, reduce costs and thereby boost customer satisfaction.”

Automated management of entire logistics, including production, sales, and delivery help achieve energy efficiency and optimized processes. Another essential advancement is that sensors are becoming smaller, and smarter allowing more intelligent transportation systems that are able to collect data about environmental and traffic conditions, improve communications, reduce accidents and be environmentally friendly.

Final Thoughts

The more I learn about the Fourth Industrial Revolution, the more there is to explore. It’s an endless space of smart objects, interconnections, disruptions, transformations, and opportunities.

I wonder if I had a time machine and could go 5 years forward, would I recognize the world? Some predictions say it will be a place where we can see fully 3D printed cars on the roads, a place where we can connect to one another via embeddable mobile phones, where we will have smart, domestic robots in homes, and where digitization will transform healthcare allowing proactive intervention in early detection, treatment of various diseases, patient-specific 3D-printed transplants, and more.

I’m looking forward to seeing these innovations coming to life and I believe that the world will benefit if we manage to use nature-based and human-centered technologies the right way.