Table of Contents

Technological advancements in Artificial Intelligence (AI), robotics, and 3D printing are rapidly transforming the manufacturing and AEC (Architecture, Engineering, and Construction) industries. These innovations are not only streamlining operations and increasing productivity but also unlocking new possibilities in design, production, and customization. In response to increasing demands for efficiency, sustainability, and personalized products, these sectors are turning to digital tools and automated systems to stay competitive.

AI is revolutionizing manufacturing by optimizing supply chains, predictive maintenance, and production workflows. Robotics is automating repetitive and labor-intensive tasks both in factories and on construction sites, improving precision and safety. Meanwhile, 3D printing is enabling the creation of intricate components and entire structures, often at lower costs and with minimal material waste.

Alongside these trends, web-based platforms and computational design tools are emerging as powerful enablers of customization at scale. These tools empower designers, engineers, and consumers to collaboratively shape products and structures in real-time, making mass customization more accessible than ever. In this article, we’ll explore the latest trends and innovations in AI, robotics, and 3D printing, and examine how these technologies are converging to redefine the future of manufacturing and construction.

AI is the New Brain Behind Manufacturing and AEC

AI has quickly become a critical player in both manufacturing and construction, transforming everything from project management to quality control. Major corporations are already reaping the benefits of AI-driven analytics and automation.

AI in Construction Planning

Source : Boston Dynamics

In the construction world, AI is being used to optimize project schedules and budgets. For example, Boston Dynamics has introduced Spot, a four-legged robot equipped with AI to monitor progress on construction sites. The robot scans the site to compare actual progress against the project’s digital plans, identifying delays, design errors, and potential risks in real time. This enables project managers to make quick decisions, avoiding costly mistakes and delays.

Predictive Maintenance in Manufacturing

Siemens, a global leader in industrial automation, uses AI to monitor factory equipment in real-time, predicting machine failures before they occur. By analyzing historical data from sensors, AI systems can identify early signs of wear and tear, helping avoid costly breakdowns. This technology has reportedly cut equipment downtime by up to 30% in Siemens’ factories worldwide, delivering significant cost savings.

Robotics: Taking on the Heavy Lifting in Manufacturing and Construction

Robots have long been integral to manufacturing, but they are now making a significant impact in construction as well, taking on roles traditionally held by human labor.

Automated Bricklaying with Robotics

Source : Fastbrick Robotics

Construction robotics company Fastbrick Robotics has developed Hadrian X, an automated bricklaying robot capable of laying over 1,000 bricks per hour. This robot was used to build a home in under three days in Western Australia, a project that would typically take weeks with traditional methods. With such technologies, construction firms are cutting down on labor costs and project timelines while ensuring consistent, high-quality work.

Collaborative Robots in Manufacturing

Source : Universal Robots

Cobots (collaborative robots) are playing a crucial role in the automotive industry, where they work alongside human workers. For instance, ‘Universal Robots‘ cobots are used in automotive assembly plants to assist with intricate tasks such as assembling small components, polishing surfaces, and applying adhesives. These cobots are programmed to handle repetitive tasks with high precision, reducing worker fatigue while enhancing overall productivity.

3D Printing: Redefining Production and Construction

3D printing is one of the most disruptive technologies in both sectors, enabling faster production, reduced material waste, and previously impossible designs.

3D Printed Homes

Source : ICON 3D Printed homes

In Austin, Texas, ICON, a 3D printing construction startup, has partnered with homebuilder Lennar to print homes. These houses are built using ICON’s Vulcan printer, which extrudes concrete layer by layer, forming walls and structural components with minimal waste. ICON’s 3D printing technology has already created affordable housing for low-income families and is currently used in large-scale projects like NASA’s Lunar Base construction plan.

3D Printing in Aerospace Manufacturing

Source : Boeing additive manufacturing

Aerospace giant Boeing is leveraging 3D printing to produce complex aircraft parts. The company uses additive manufacturing to print lightweight titanium parts for its 787 Dreamliner, which cuts material costs by up to 50%. By reducing the weight of aircraft components, Boeing is not only saving money but also improving fuel efficiency, an essential factor in today’s aviation industry.

3D Printing in Bridge Construction: MX3D Bridge in Amsterdam

Source : MX3D Bridge in Amsterdam

The MX3D Bridge in Amsterdam, the world’s first 3D-printed steel bridge, highlights 3D printing’s potential in construction. Using robotic arms, MX3D printed the 12-meter bridge layer by layer with stainless steel, achieving a complex, custom design that traditional methods couldn’t easily replicate. This project demonstrates 3D printing’s ability to create large-scale, load-bearing structures efficiently, with minimal waste, and in challenging environments.

Real-World Convergence of Technologies

The convergence of AI, robotics, and 3D printing is beginning to define modern construction and manufacturing, creating more integrated, autonomous processes.

Digital Twins in Smart Factories

In BMW’s Munich-based smart factory, digital twins—AI-powered virtual models of physical systems—are used to simulate production lines before they are implemented. This allows engineers to test and optimize processes in the digital realm, avoiding costly real-world inefficiencies. The factory also integrates autonomous robots and 3D printing to streamline car assembly, making it one of the most advanced manufacturing facilities in the world.

Sustainable Construction with Advanced Robotics and 3D Printing

In Dubai, Apis Cor used a giant 3D printer to create a two-story municipal building, the world’s largest 3D-printed structure at the time. By combining AI algorithms to monitor construction and precision robotics to build walls, the company reduced material waste by 60% and cut project costs by 40%. This project is a glimpse into the future of sustainable urban development.

The next era of Design Software

As AI, robotics, and 3D printing revolutionize manufacturing by automating processes, enhancing precision, and enabling complex production, the need for agile, scalable design tools becomes even more critical. This is where cloud-based software platforms come into play. Just as AI optimizes production workflows, cloud-based tools empower designers and manufacturers to collaborate, customize, and innovate in real-time. With the rise of mass customization and on-demand production, platforms that can handle dynamic, data-driven designs are essential.

AI-Driven Design Optimization : Flinch 3D

Source: Flinch 3D

Design tools like Flinch 3D are changing the architecture and engineering fields by using AI and advanced algorithms to create parametric, data-driven designs. Flinch 3D helps architects and engineers improve their design processes through real-time collaboration and continuous optimization.

Flinch 3D uses generative technology to quickly iterate design concepts based on factors like environmental conditions, budget constraints, and user requirements. This allows users to explore many options, automatically generate floor plans for different stories and units, and continuously refine their designs easily. The platform also speeds up decision-making by providing instant feedback on design performance. By using data effectively, Flinch 3D streamlines feedback loops, helping users make informed choices quickly.

One of its key features is built-in error prevention, which ensures designs follow the rules and regulations set by firms, customers, and municipalities. This lets users focus on creative design work while Flinch 3D handles compliance and minimizes errors in the background.

Creating a Manufacturing Ecosystem : Beegraphy

Source: Beegraphy

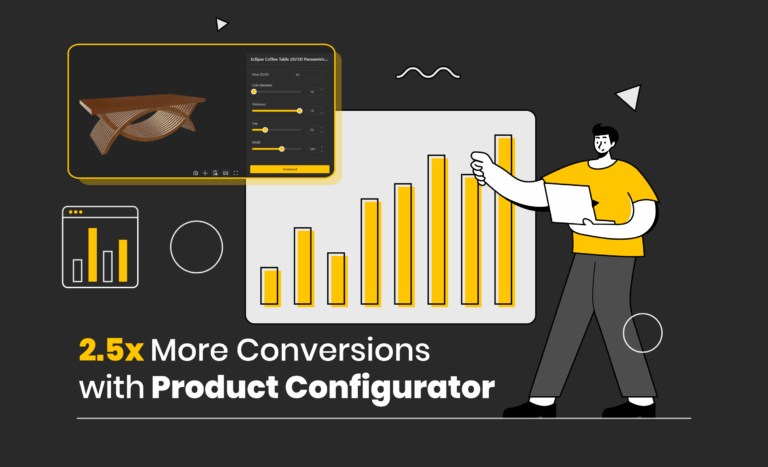

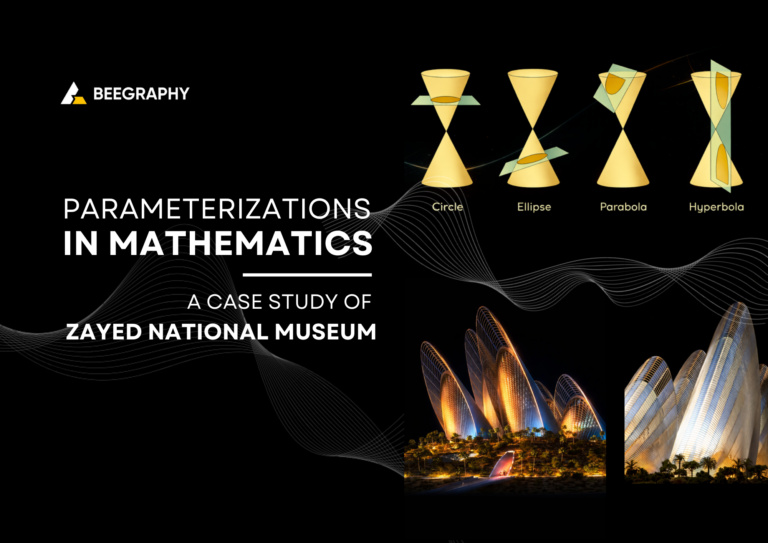

BeeGraphy aims to address some of the key pain points in the manufacturing and AEC industries through its cloud-based platform. With an intuitive interface, it facilitates real-time customization and smooth collaboration among stakeholders. Its parametric design editor allows designers and manufacturers to adjust models easily, ensuring that both functional and aesthetic requirements are met with flexibility.

The BeeGraphy Configurator further enhances this by allowing users to visualize and customize designs in real-time, ensuring a seamless transition from concept to production and reducing lead times. Additionally, BeeGraphy supports advanced 3D printing capabilities, enabling the creation of complex, high-quality components directly from parametric models.

The BeeGraphy Marketplace fosters collaboration by connecting designers, manufacturers, and customers, enabling mass customization and driving innovation.

With API integration, BeeGraphy seamlessly fits into existing workflows, allowing manufacturers to automate and scale their processes efficiently. By offering a comprehensive suite of tools for customization, collaboration, and automation, BeeGraphy is pushing the boundaries of design and production, empowering industries to meet the growing demand for personalized, cutting-edge solutions.

Conclusion: Building the Future Together

Just like pieces of a puzzle coming together to reveal a bigger picture, AI, robotics, and 3D printing are joining forces to transform manufacturing and construction. These technologies aren’t working in isolation; they’re connecting to create new possibilities we couldn’t have imagined a few years ago.

Think of it as an orchestra where each instrument—AI, robotics, and 3D printing—plays its part to create a harmonious symphony. AI provides the score, guiding decisions and predicting outcomes. Robotics performs with precision, handling tasks that require strength and accuracy. 3D printing adds creative flair, allowing us to produce complex designs that were once out of reach.

As these technologies blend, we’re entering a new era where the boundaries between what’s possible and impossible are blurring. Tools like Flinch 3D and BeeGraphy are like conductors, helping different parts work together seamlessly, making collaboration and customization easier than ever.

Looking ahead, the integration of these technologies will continue to reshape how we design and build, much like how a river shapes the landscape it flows through. By embracing this convergence, we’re not just improving efficiency and sustainability; we’re opening doors to innovation and creativity that reflect the diverse needs of our world. The future isn’t some distant horizon—it’s being built right now, with each new connection and collaboration paving the way.