Table of Contents

Introduction

Computer-Aided Design (CAD) has revolutionized the way engineers, architects, and designers create and design complex parts and systems. Since its inception in the early 1960s, CAD has undergone significant advancements, making it more accessible and user-friendly.

Today, CAD software is used in a wide range of applications, from architecture and engineering to product design and gaming. In this article, we will explore the evolution of CAD and its impact on smart manufacturing markets growth. We will also discuss the latest industrial design trends and innovations.

The Evolution of CAD

In the early days, CAD systems were primarily used in the aerospace and automotive industries. These early systems were primitive and often large, expensive, and difficult to operate. However, they were a significant improvement over traditional manual drafting methods, which were slow, prone to error, and limited in their capabilities.

The most demanded CAD solution in industrial manufacturing currently is cloud-based computing

Over the decades, CAD systems have undergone significant advancements, making them more accessible and user-friendly. One of the latest trends is the rise of cloud-based platforms like BeeGraphy, which offer seamless, cross-platform compatibility and eliminate the need for complex installations. With the ability to create models in the cloud and share them through a simple URL link, users can collaborate and co-create in real-time from anywhere in the world.

Another emerging trend is the use of 3D visual product configurators, which allow customers to customize and visualize products before purchasing. BeeGraphy’s 3D visual product configurators are more accessible and affordable than ever, allowing businesses to automate the sales process of customizable products online.

To truly unlock the full potential of computational design, it is essential to integrate it with other business processes. BeeGraphy’s API allows users to integrate the platform’s parametric geometry engine into e-commerce platforms to speed up sales and manufacturing business processes.

Smart Manufacturing Markets Growth

Together with other technologies, CAD software now allows not only to create digital visuals, but also to communicate, analyze, and boost the efficiency of working processes

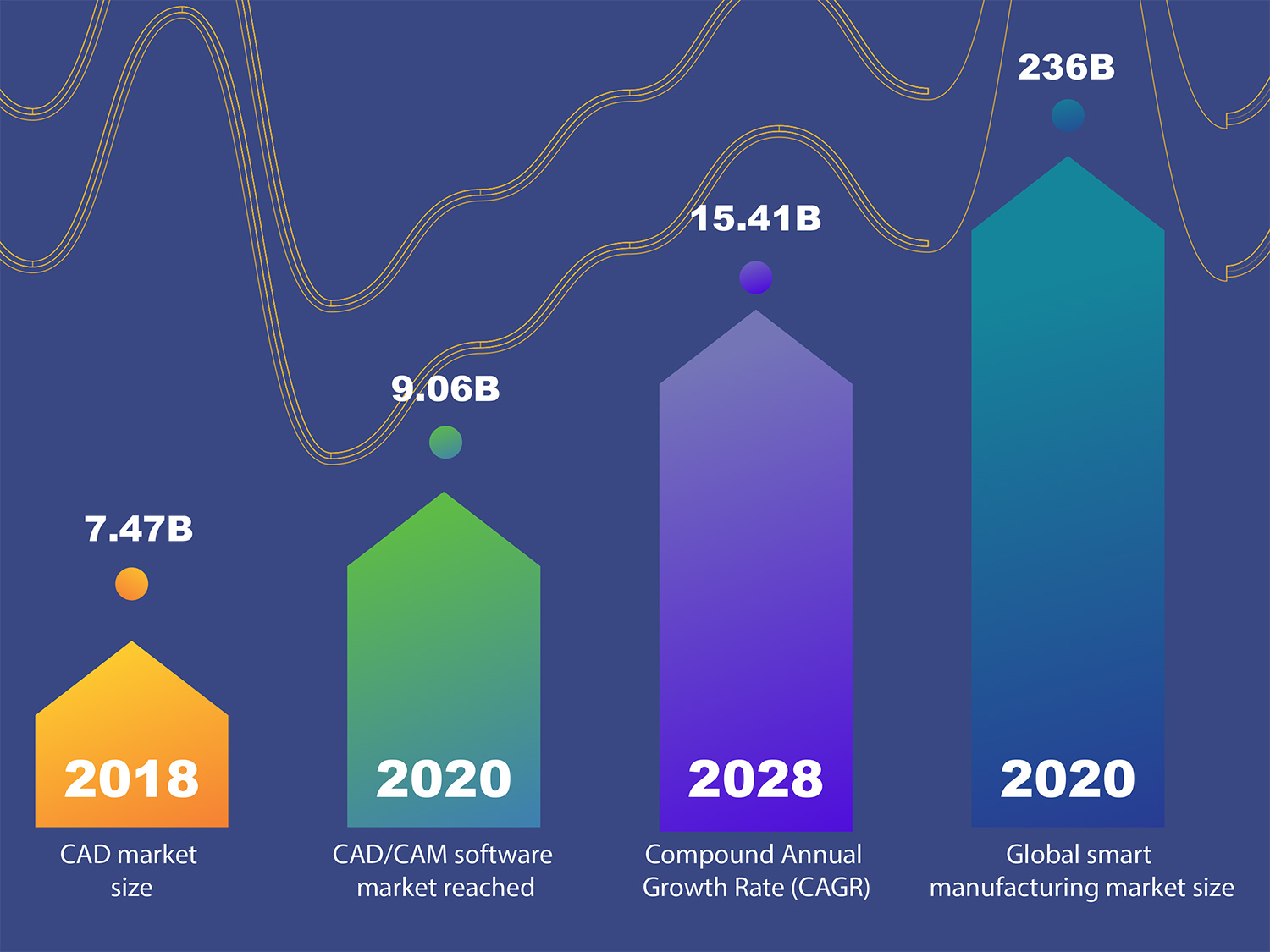

CAD has played a significant role in smart manufacturing markets growth. The global CAD market size in 2018 was around 7.47 billion. In 2020, the CAD/CAM software market reached $9.06 billion. The most demanded CAD solution in industrial manufacturing currently is cloud-based computing. According to Grand View Research, in 2020, the global smart manufacturing market size was estimated at around $236 billion.

Industrial design market size is expected to grow at a CAGR of 5.85% and surpass $61 million by 2025. Germany and the USA led the rankings in industrial design applications worldwide in 2020. Statistics for CAD designers in the US show that there are over 59.773 specialists employed.

CAD industry & smart manufacturing markets growth

The latest industrial design trends and innovations

The latest industrial design trends and innovations are taking the design creation process and manufacturing to another level. CAD, along with other Industry 4 technologies, continues to revolutionize these processes.

Artificial Intelligence

One of the leading ultimate trends in the CAD industry is Artificial Intelligence (AI). AI can be integrated into CAD software to enhance productivity, reduce errors, and automate processes. AI algorithms can also help designers and engineers find optimal design solutions, analyze data, and generate simulations.

CAD with Cloud Computing

Cloud-based CAD platforms like BeeGraphy are one of the most promising innovations in CAD. They offer seamless, cross-platform compatibility and eliminate the need for complex installations. With the ability to create models in the cloud and share them through a simple URL link, users can collaborate and co-create in real-time from anywhere in the world.

Robotics

Robotics is another promising innovation in industrial design. Robots can be used in the manufacturing process to increase efficiency, reduce costs, and improve safety. They can also be used in the design process to create accurate and complex models and prototypes.

Internet of Everything

The Internet of Everything (IoE) is a concept that connects everything, including machines, devices, and people, to the internet. IoE offers several benefits for industrial design, such as real-time data monitoring, predictive maintenance, and improved supply chain management. For example, by using sensors and connected devices, businesses can track and analyze their production process in real-time, identify potential issues, and optimize their production output.

Virtual Reality

Virtual Reality (VR) is another exciting innovation that is transforming the industrial design industry. With VR, designers and engineers can create realistic, immersive virtual environments to visualize and test their designs before production. This technology allows businesses to reduce the time and costs associated with physical prototyping while improving the accuracy of their designs.

Conclusion

The evolution of CAD has been instrumental in transforming industrial design and manufacturing processes, making them more accessible, efficient, and cost-effective. The latest trends and innovations, such as cloud-based CAD platforms, AI, robotics, IoE, and VR, are set to revolutionize the industry further. As businesses continue to adopt these technologies, the smart manufacturing market is set to grow even more, providing opportunities for new entrants and established players to innovate and grow their businesses.

In conclusion, the evolution of CAD and its impact on smart manufacturing markets growth has been significant, and it continues to shape the future of industrial design and manufacturing. To stay ahead of the curve, businesses need to embrace the latest trends and innovations, such as cloud-based CAD platforms, AI integration, and robotics. By doing so, they can increase their productivity, reduce costs, and improve the quality of their products. So, whether you’re a designer, engineer, or manufacturer, it’s time to embrace the power of CAD and take your designs to the next level. Don’t be left behind; start exploring the latest CAD innovations today and join the smart manufacturing revolution!